Results from a newly published study (and one I’ll possibly summarise in the future).

It explored the status of human factors and ergonomics (HFE) metrics in the context of product realization in an electronics manufacturing company.

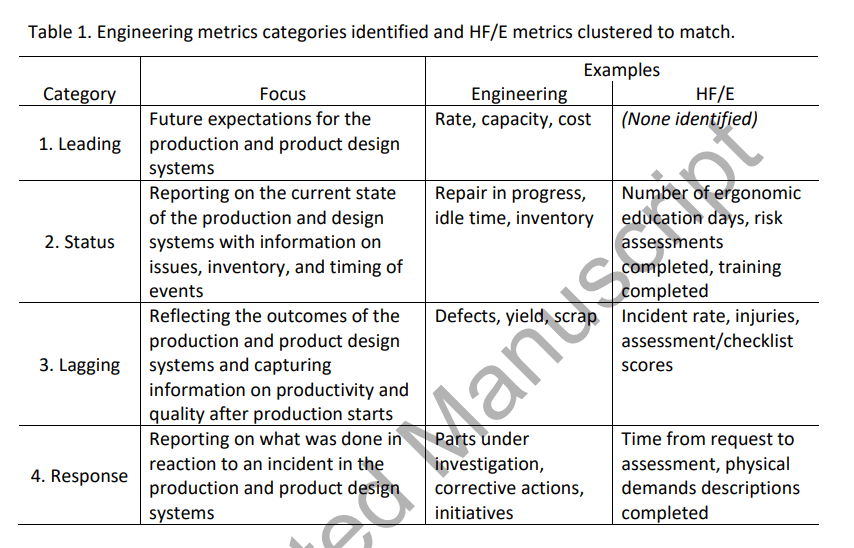

Five engineering metrics were categorised and matched to HFE metrics:

Key findings included:

· HFE metrics were most commonly observed in the status and lagging categories

· HFE status metrics reported on how the HFE group completed their service to the organization

· HFE lagging metrics (indicators after the point operations were initiated), typically reported injuries and incident rates

· There were no leading measures and few response metrics

· HFE metrics were said to be “health-oriented and disconnected from quality and productivity aspects”

· HFE stakeholders were aware that the HFE measures weren’t well aligned to the organisation’s existing process of new product realisation & design

· One person commented that current lagging info of injury and discomfort measures, or “status reporting on ‘ergo visits’ “doesn’t mean a whole lot and reflect everything that is done, or [we’re] trying to do, to improve [the] ability for people to do work”

· While engineering metrics were more directly connected to manufacturing execution and the system, the HFE metrics were more targeted at the workstation.

They provide 7 steps to move forward in this context:

1) Look for gaps that exist between the metrics and indicator information that you communicate and the scope of the information communicated by the group you are looking to work with

2) Determine the motivation for metrics and indicators – for the organisation and the individual, and make sure that you have information to be impactful at the different levels in the system

3) Connect to strategic goals and/or individual goals in the organisation to move HF/E beyond a health and safety focus and gain key stakeholder support

4) Appreciate the background knowledge of the target audience. Educate as required and adapt your communication to their strengths and organisation context

5) Create information in a style that is familiar to the audience and with an appropriate amount of detail

6) Be mindful of perceptions of the credibility of the data and data gathering processes

7) Create processes that integrate with existing workflow or add minimal work. Identify appropriate timing to introduce new concepts and demonstrate the importance to their role or the organisation

I think these findings highlight a problem more broadly in HSE also -often there’s few quality measures connected to the improvement or management of work.

Authors: Greig, M. A., Village, J., Salustri, F. A., & Neumann, W. P. (2023). Examining human factors and ergonomics aspects in a manufacturing organisation’s metrics system: measuring up to stakeholder needs. Ergonomics, (just-accepted), 1-22.

Study link: https://doi.org/10.1080/00140139.2023.2168065

Link to the LinkedIn post: https://www.linkedin.com/posts/benhutchinson2_results-from-a-newly-published-study-and-activity-7025247932790562816-clwx?utm_source=share&utm_medium=member_desktop

One thought on “Examining human factors and ergonomics aspects in a manufacturing organisation’s metrics system: measuring up to stakeholder needs”