This systematic review evaluated Job Safety Analysis (JSA) research to answer the following:

(1) Which sectors and areas have used JSA?

(2) What has been the aim of employing JSA?

(3) What are the shortcomings of JSA?

(4) What are the new advances in the field of JSA?

Providing background:

· While different definitions, goals and designs exist for JSAs, they note JSAs generally aim to ID hazards of a task, assess the risks and prevent losses by listing control measures; use for training is another purported aim

· They state that “Many retrospective studies have found that implementing a proper JSA is effective in preventing accidents [6,7] and promoting safety behavior [8]”

· Other work from Albrechtsen argued that JSA have at least six benefits: (1) formalization of work, (2) accountability, (3) participation of employees, (4) organizational learning, (5) hazard identification and situation awareness, and (6) loss prevention

NB. I’ve skipped most of the background material.

Results

Use across industries

Expectedly, JSA has been widely adopted across industries. It was most frequently observed in construction (31% of instances), process industries (24% cases) and healthcare (8%).

In construction, JSA was found to be used for most tasks and operations, whereas in the process industries the literature described a focus more as a supplement to process HAZID techniques.

In healthcare, it was found to be widely used for HAZID and risk assessment in emergency departments, operating rooms and patient critical cares.

It was also found to be used, but less widely, in manufacturing, forestry, fishing and more.

JSA Objectives

Summarising this section:

· 51% of articles highlighted JSA as a technique for HAZID

· 49% for both HAZID and risk assessment

· 78% of studies described or used JSA as a technique for assigning appropriate control measures and hazard/risk communication

· Several studies also used JSAs for more specific objectives, like the selectin of PPE, developing a special safety program, assessing the effectiveness of interventional programs and more

Risk assessment

24 studies used the JSA to undertake a risk assessment. There was wide variability in the risk assessment methods, with some using self-developed methods, six used the MIL-STD-E882 standards, two used US/NZ standards, and then a scattering of other methods.

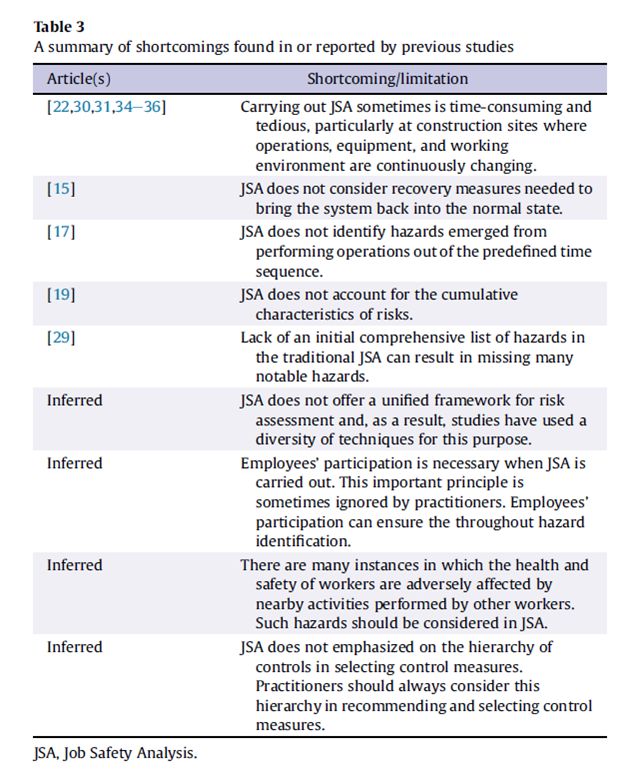

Limitations of JSA

As shown in the below table, several limitations were identified in JSAs methods.

They note that “being tedious and time-consuming to perform was the most frequent drawback mentioned by studies”.

Another apparent shortcoming was a “Lack of a comprehensive initial list of hazards” for operators to work from [* some may challenge whether this is actually a shortcoming]

Listing other limitations/shortcomings:

· Lack of a universally accepted risk assessment framework to accompany JSAs

· Lack of worker participation in the process, since many studies didn’t explicitly mention the degree of worker participation

· Only 37% of the 49 articles mentioned that the JSA was completed by a team

· Inability of JSA to assess the effect of hazards posed by nearby activities [** The hazard posed by the interaction of multiple work crews has been identified in several other construction studies, see my site for articles]

· On this, they argue “JSA is carried out based on the general working environment and ignores nonroutine/routine conditions in which the health and safety of workers are threatened by surrounding activities” [** Weakness of JSA/safe work methods to effectively consider non-routine activities is also a well-documented finding in the construction literature, see my site]

Advances/Innovation in JSA

I’ve skipped this section (the full paper provides a table of their findings), but they also explored how some companies are expanding or innovating on the use of the JSA. It includes things like machine learning and the like.

If you’re interested in this area then check out the paper.

Discussing the findings, they conclude that “JSA suffers from a number of serious shortcomings”, including being time-consuming, which makes “supervisors and employees reluctant to conduct the method and use its benefits before starting the work”.

This problem appeared to be “more prominent at construction sites where frequent JSAs are needed because of changing nature of working conditions and equipment participation”.

Regarding the “lack of a comprehensive list of hazards”, they suggest considering complimentary approaches like energy-based JSAs and the like, which focus on identifying the sources and release mechanisms of hazardous energy.

Energy-based methods also have limitations, for instance they frequently under-perform with psychosocial hazards.

They also argue that it’s not clear how effective the control measures specified in JSAs are managing operational risks, because of wide inconsistencies in risk assessment methods.

As mentioned previously, many JSAs lack the structural and operational considerations of surrounding activities such that “As JSA focuses on the task performed by the employee [or work group], such hazards [surrounding work and crews] may be missed even though they can have an adverse impact on the health and safety of the employee”.

Moreover, only a few studies in this sample mentioned the hierarchy of control; hence, based on this systematic review, few documented applications of JSAs explicitly consider the hierarchy of control.

Authors: Ghasemi, F., Doosti-Irani, A., & Aghaei, H. (2023). Safety and Health at Work.

Study link: https://doi.org/10.1016/j.shaw.2023.03.006

Study link: https://www.linkedin.com/pulse/applications-shortcomings-new-advances-job-safety-jsa-ben-hutchinson-amyme

One thought on “Applications, Shortcomings, and New Advances of Job Safety Analysis (JSA): Findings from a Systematic Review”