This paper interviewed 23 safety professionals from 17 companies, and evaluated JHA documents, surrounding the obstacles and solutions to implementing Job Hazard Analysis/Job Safety Analysis (JHA) in construction.

Providing background:

- Despite the widespread use of JHAs in construction, there “currently lacks comprehensive guidelines on how to effectively design and implement JHA on a consistent basis”

- They argue that the lack of guidance, and dynamic nature of construction involving multiple stakeholders, large number of tasks may leave excessive degrees of freedom on how to effectively design and use JHAs.

- Some prior research has highlighted benefits of JHA/JSAs. One found that the frequency of pre-work hazard ID by the work crews positively correlated with project safety performance and reduced injury rates

- Another study found that more time invested in communicating hazards between workers was associated with lower incident rates

- The authors discussed several potential means of improving the JHA process, including text classification, ontological and semantic modelling, automating JHA processes, risk prediction methods, human factors analysis and more – but thus far most of these means are aimed at organisational levels rather than for operational crews

Results

Overall, obstacles to JHA effectiveness were found to include:

- A lack of worker involvement in the process, lack of buy-in

- management absence

- complacency [* or optimisation]

- inadequate coordination and communication

The authors discussed several means for improving the process, including use of visual aids, rotating JHA meeting leaders, and continuous updating JHA info to reflect current work conditions, but I’ve largely skipped most of these discussions.

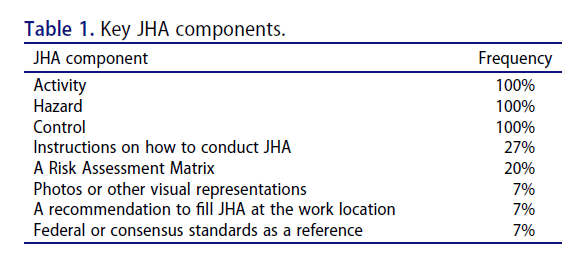

First based on the JHA document analysis (30 JHAs), it was found that the activity, hazard and control sections were the only components present in all 30 JHAs. The specificity of info also varied in each JHA, e.g. some JHAs had general PPE through to highly specific PPE in others.

Lack of reading proficiency and language barriers were recognised as two major obstacles to effective JHA processes.

Moreover, workers would not remain invested in the process, lack attention to details, had problems understanding or describing task assignments and associated hazards, and additional JHA obstacles were long, wordy documents.

Some suggested use of mini-JHA cards with only task-specific info rather than high-level general info. This could include some basic “life-saving actions” for each hazardous condition.

Using visual aids was recognised as an effective concept to enhance the quality of JHA documents. This could include: (1) manufacturer drawings of the tools and equipment, (2) photos or illustrations of the task in stepwise order, and (3) pictograms showing safety and hazard categories.

Jobsite maps were also identified as useful to help workers and contractors coordinate daily activities. One suggestion was the use of unique colour codes assigned to each contractor on one jobsite, and icons to depict high-risk activities.

Lack of buy-in to the JHA process was identified as a major problem. This is amplified by “aggressive schedules and multiple competing responsibilities”. Further, “some crew members may perceive JHAs as unnecessary paperwork, especially if they appear wordy, complicated, or time-consuming”.

Respondents in interviews used phrases to describe JHAs like “pencil whipped,” or completed superficially without digesting and understanding the content”.

The more experienced operators noted that the “push for regular JHA is a recent initiative”. Part of the lack of buy-in to JHA is that the impression that completed JHA documents “will sit unused on a bookshelf or get lost in the process or discarded”. [Or as other research has identified, the impression is that JHAs are used as arse covering by the organisation to blame operators.]

Suggestions to improve buy-in included encouraging personalisation of the JHA, incorporating real-life experiences into JHAs augmented with video footage or images and more.

Lack of effective communication was another obstacle. This was reflected in things like no systematic approach to frequently and adequately communicating jobsite changes and updates to workers, lack of communication skills in some team members, insufficient time mentoring junior workers and more.

Next they observed that gaps between the JHA and actual work was another major issue. It was learned that “JHA documents are usually developed by mid- or upper-level managers who are not regularly present on the jobsite or physically involved in task performance” and resultingly “some JHAs may not match the most recent job conditions”.

JHA documents were also found to be “typically driven by regulatory and consensus standards rather than the actual task requirements and workers’ input”.

Discussing the findings, they note that these findings “indicate that the importance of JHA may not be fully realized by work crews”.

Overall, they highlight the “the role of management in optimizing the content, design, and delivery of the JHA process”; where information accessibility and ease of use should be critical factors in these efforts.

For ways to improve, they suggest:

(1) proactively coordinate the use of a consistent format among all project stakeholders,

(2) strengthen site safety climate by optimizing JHA content and format for ease of use by craft workers,

(3) perform regular field audits and solicit craft worker feedback, and

(4) institute a continuous improvement cycle to ensure that JHA content reflects current jobsite conditions in the dynamic construction environment.

Finally, as part of the PDCA cycle and the emerging nature of construction work and hazards, they suggest it critical to “gather and document end-of-shift information, especially workers’ feedback, to address newly emerged hazards and whether the work process deviated from the JHA discussed at the beginning of the shift”.

Authors: Babak Memarian, Sara B. Brooks & Jean Christophe Le (2023). International Journal of Construction Education and Research, 19:2, 187-198

Study link: https://doi.org/10.1080/15578771.2022.2027053

LinkedIn post: https://www.linkedin.com/pulse/obstacles-solutions-implementing-job-hazard-analysis-case-hutchinson-mguoc

One thought on “Obstacles and Solutions to Implementing Job Hazard Analysis in Construction: A Case Study”