This compendium covers several themes relating to safety performance indicators / risk indicators / process safety indicators.

The following topics are covered:

- Indicator definitions

- Leveson and Systems Engineering/Systems Safety

- Frameworks, logics and other

- Indicator Examples (probably what most people want to see)

- Psychosocial Indicators

- Caveats, limitations, advice on indicators

- Relationship with Performance and Other Measures

Note:

- I’ve only covered a tiny amount of the process safety field – there’s literally textbooks devoted to this topic

- I haven’t repeated the Safety-II/Resilience Engineering indicators here – check out these compendiums instead:

- I haven’t covered healthcare, aviation or nuclear domains (plus lots more)

Indicator Definitions

Australian Constructors Association. Lead Indicators Safety Measurement in the Construction Industry: https://www.constructors.com.au/wp-content/uploads/2019/11/Lead-Performance-Indicators-Guideline.pdf

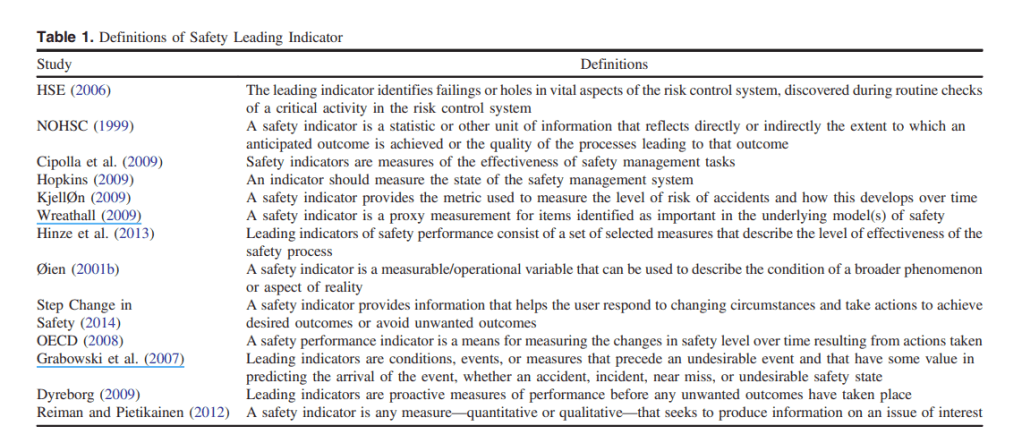

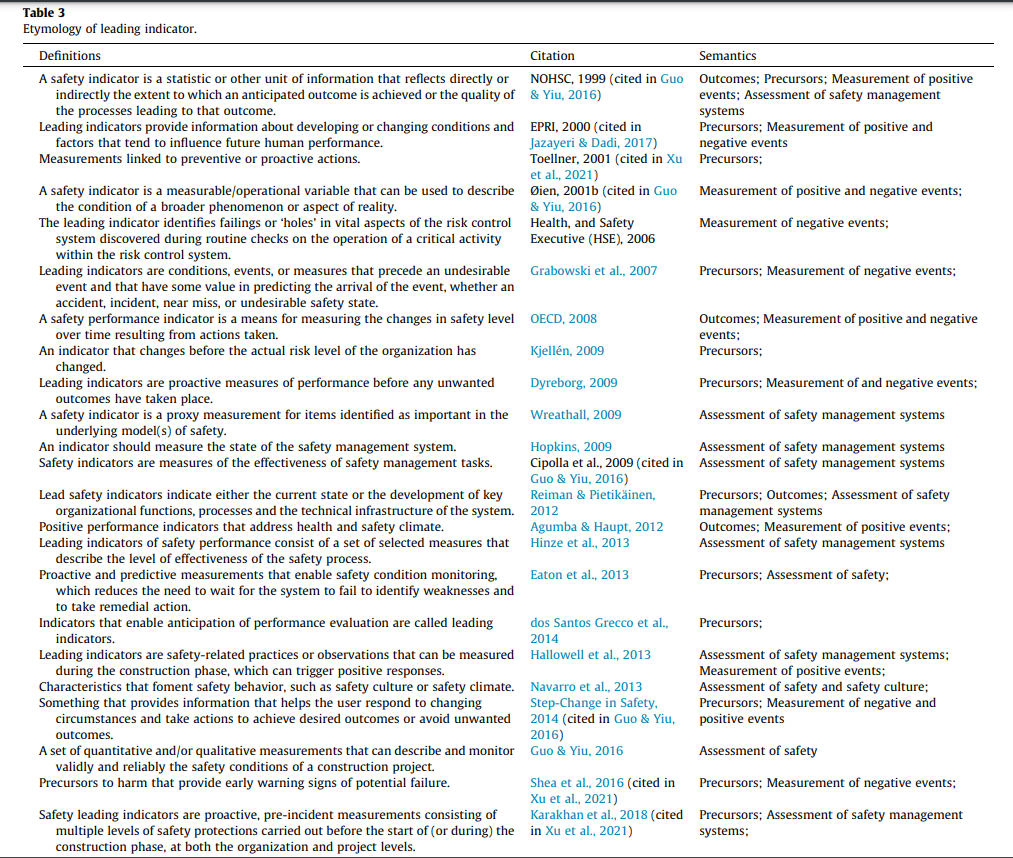

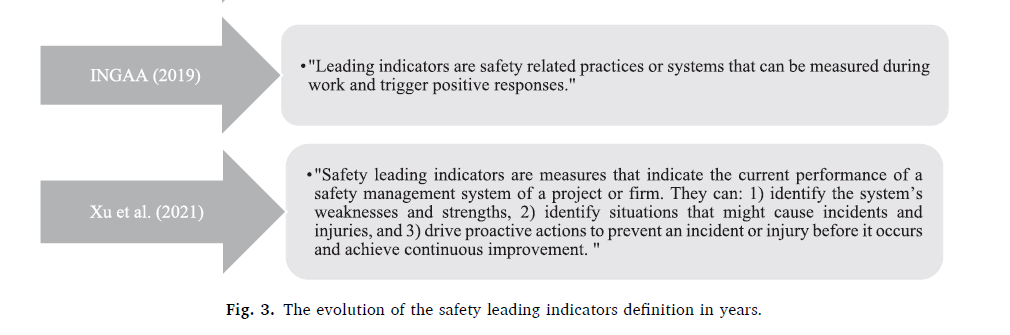

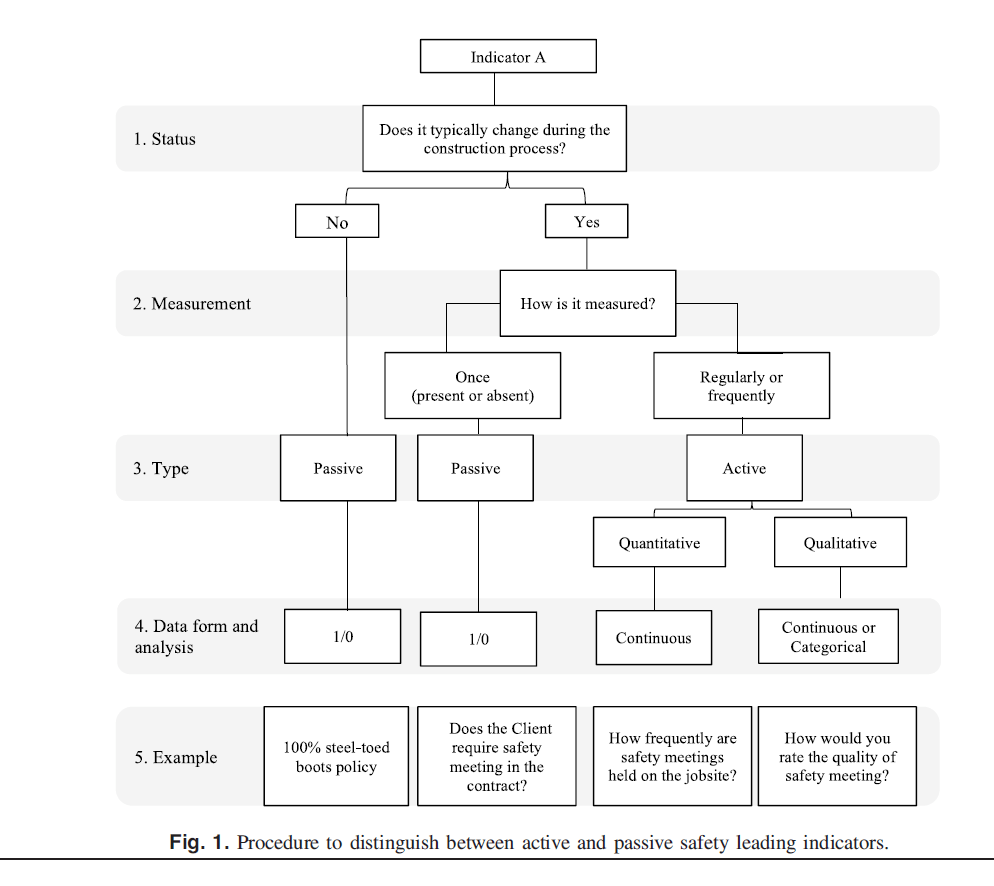

Guo, B. H., & Yiu, T. W. (2016). Developing leading indicators to monitor the safety conditions of construction projects. Journal of management in engineering, 32(1), 04015016. https://www.academia.edu/download/41620634/Developing_Leading_Indicators_to_Monitor20160127-28594-1vzn0o5.pdf

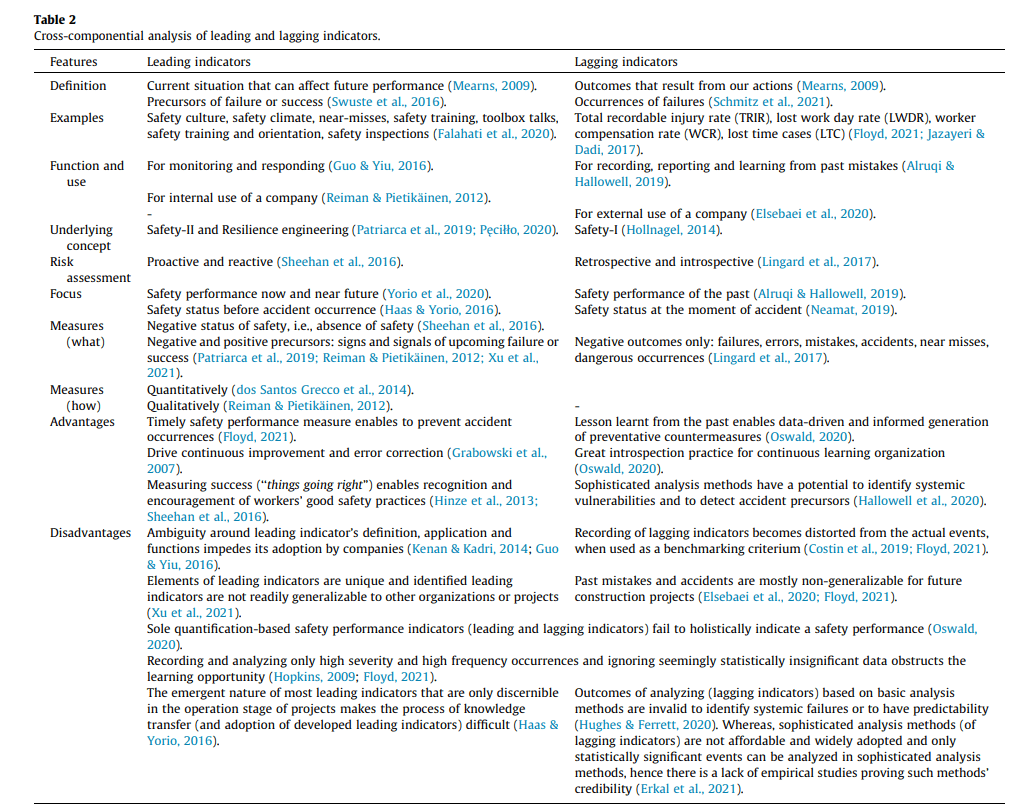

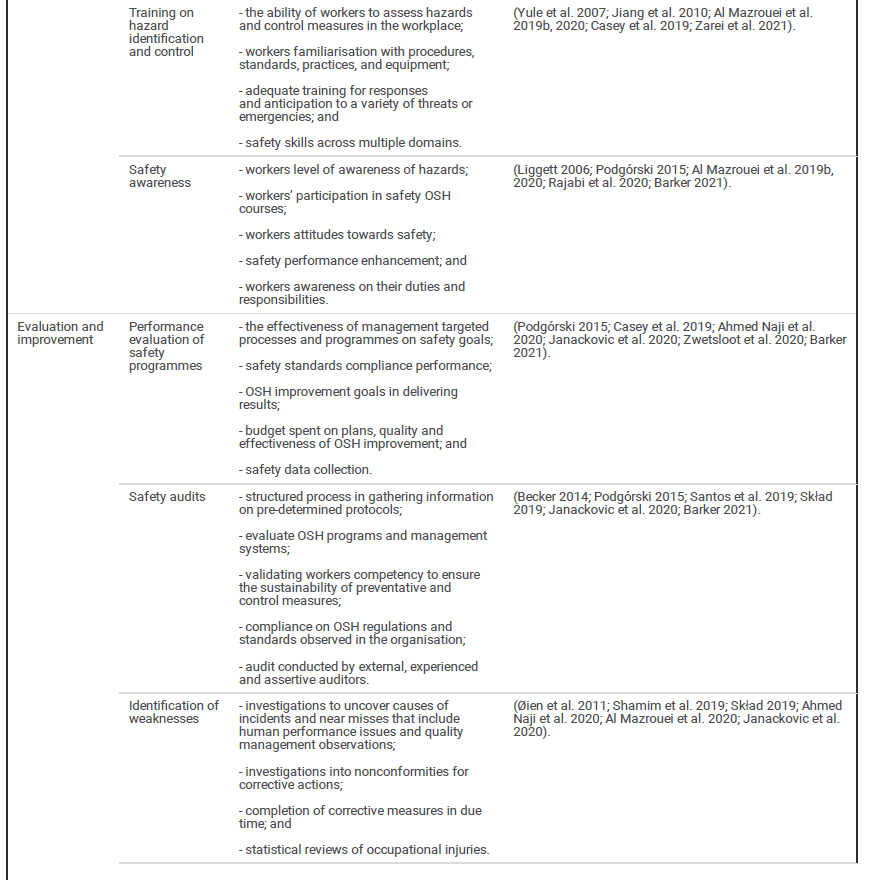

Bayramova, A., Edwards, D. J., Roberts, C., & Rillie, I. (2023). Constructs of leading indicators: A synthesis of safety literature. Journal of safety research, 85, 469-484. https://www.sciencedirect.com/science/article/pii/S0022437523000531

Stacey, J. (2012). Overview of leading indicators for occupational health and safety in mining. International Council on Mining and Metals. https://www.icmm.com/website/publications/pdfs/health-and-safety/2012/guidance_indicators-ohs.pdf

Swuste, P., Theunissen, J., Schmitz, P., Reniers, G., & Blokland, P. (2016). Process safety indicators, a review of literature. Journal of Loss Prevention in the Process Industries, 40, 162-173. https://repository.uantwerpen.be/docman/irua/1d3c6e/129952_2017_12_30.pdf

Golabchi, H., Abellanosa, A. D., Lefsrud, L., Pereira, E., & Mohamed, Y. (2024). A comprehensive systematic review of safety leading indicators in construction. Safety science, 172, 106433.

Bayramova, A., Edwards, D. J., Roberts, C., & Rillie, I. (2024). Unravelling the Gordian knot of leading indicators. Safety Science, 177, 106603. https://www.sciencedirect.com/science/article/pii/S0925753524001930

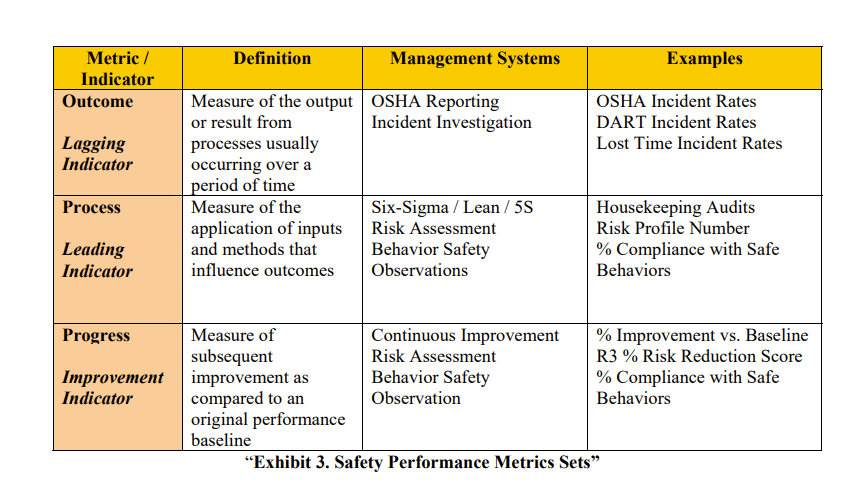

Eaton, G. H., & Little, D. E. (2009, June). Performance Metrics-Leading Indicators Deliver Sustainable Results. In ASSE Professional Development Conference and Exposition (pp. ASSE-09). ASSE. https://aeasseincludes.assp.org/proceedings/2009/docs/612.pdf

Lofquist, E. A. (2010). The art of measuring nothing: The paradox of measuring safety in a changing civil aviation industry using traditional safety metrics. Safety science, 48(10), 1520-1529. https://www.sciencedirect.com/science/article/pii/S092575351000127X?casa_token=QS0Yf1Es4A0AAAAA:GPkpiScDHOhHwKqQYj_5boGxy-au4XdQRqfBHY24bY9o_eQ8QrtnjoF2JKhKpsM2WLVzYlYJAPzY

Wurzelbacher, S., & Jin, Y. (2011). A framework for evaluating OSH program effectiveness using leading and trailing metrics. Journal of safety research, 42(3), 199-207. https://www.sciencedirect.com/science/article/pii/S0022437511000491?casa_token=XcAxz-0uQB4AAAAA:hdYkAZeMGjQaiy2e1KbeqO0Ob5UlGsiMgzuTor7kHAFjH0gnMZ9a2f-8sNkIv7f9wS3f9WOVZM6f

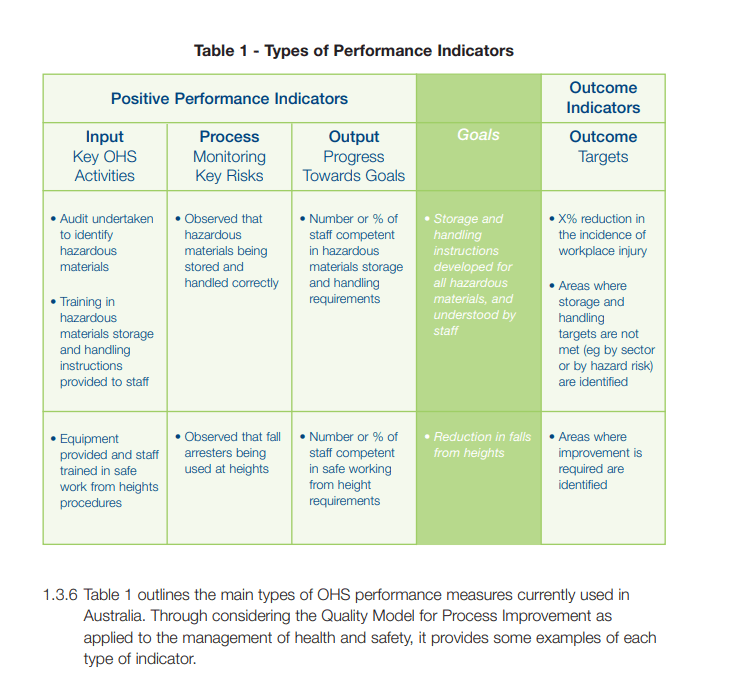

Safety, A., & Council, C. (2005). Guidance on the Use of Positive Performance Indicators to Improve Workplace Health and Safety. Safe Work Australia, Commonwealth of Australia: Canberra, Australia. https://www.safeworkaustralia.gov.au/system/files/documents/1702/guidanceonuseofppis_2005_pdf.pdf

Chen, M., Chen, Y., & Ma, S. (2021). Identifying safety performance indicators for risk assessment in civil aviation. In IOP Conference Series: Materials Science and Engineering (Vol. 1043, No. 3, p. 032010). IOP Publishing. https://iopscience.iop.org/article/10.1088/1757-899X/1043/3/032010/pdf

Leveson and Systems Engineering/Systems Safety

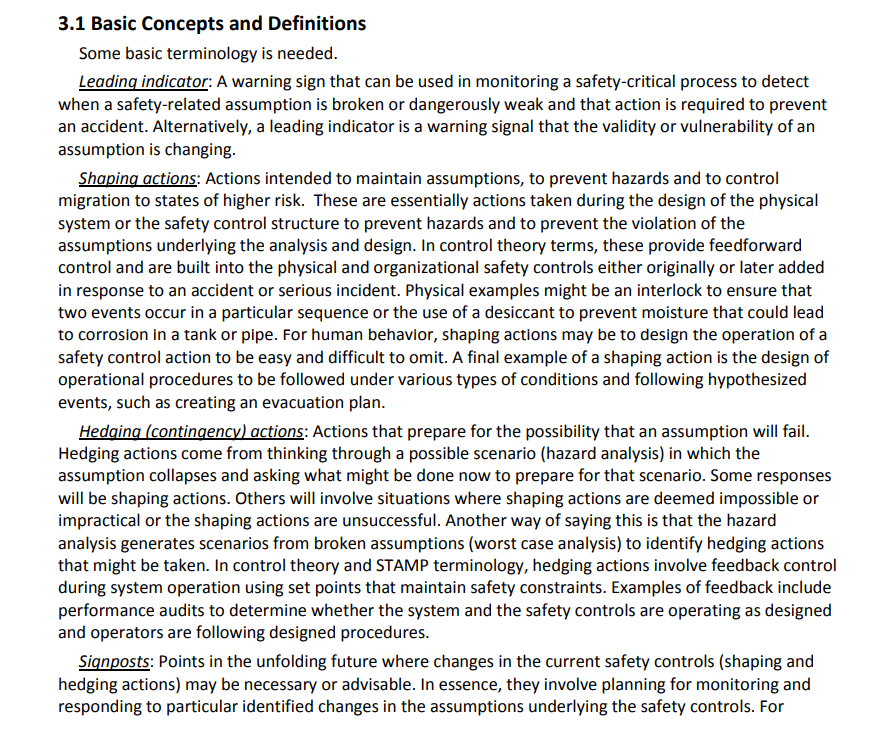

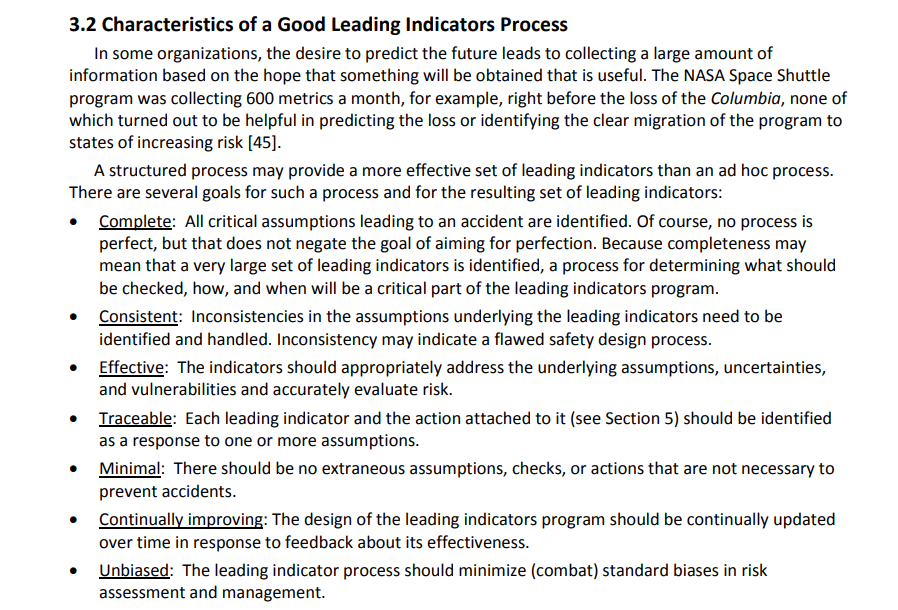

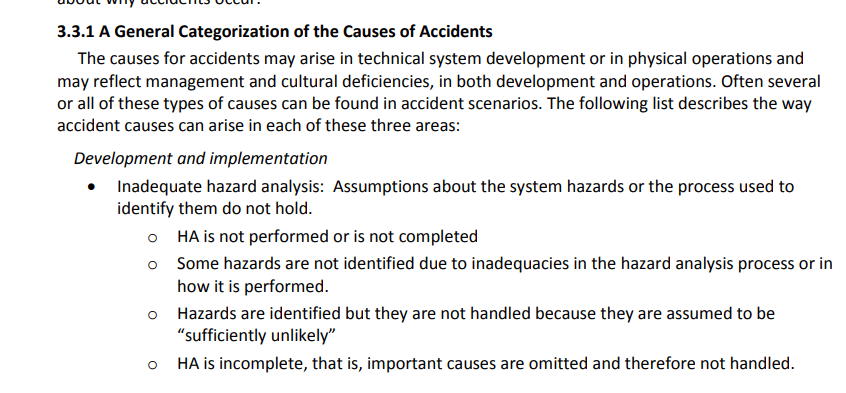

Leveson, N. (2015). A systems approach to risk management through leading safety indicators. Reliability engineering & system safety, 136, 17-34. https://dspace.mit.edu/bitstream/handle/1721.1/108601/Leveson_A%20systems%20approach.pdf

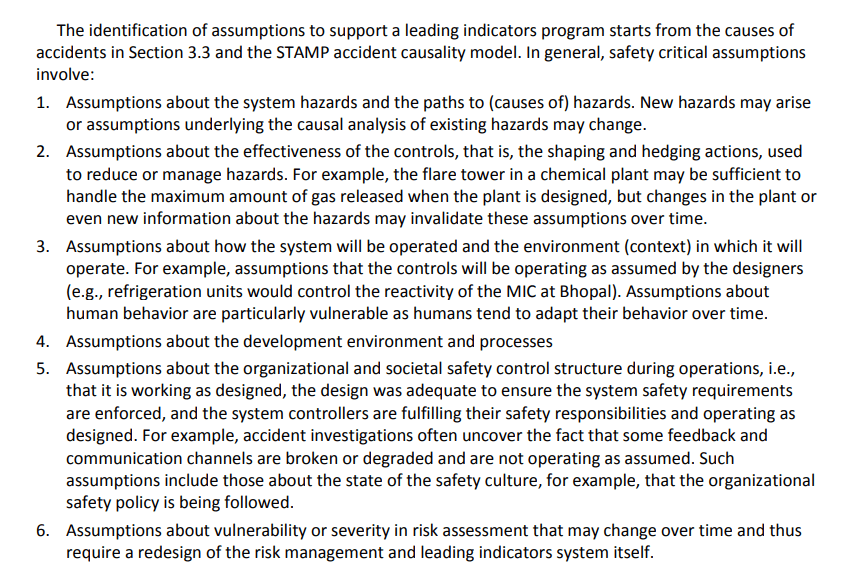

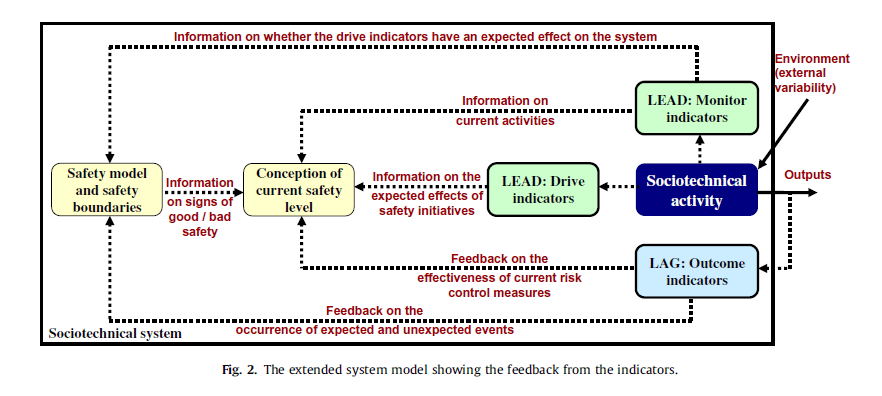

Leveson, N. (2015). A systems approach to risk management through leading safety indicators. Reliability engineering & system safety, 136, 17-34. https://dspace.mit.edu/bitstream/handle/1721.1/108601/Leveson_A%20systems%20approach.pdf

Leveson, N. (2015). A systems approach to risk management through leading safety indicators. Reliability engineering & system safety, 136, 17-34. https://dspace.mit.edu/bitstream/handle/1721.1/108601/Leveson_A%20systems%20approach.pdf

Leveson, N. G. (2013). A Systems Thinking Approach to Leading Indicators in the Petrochemical Industry. https://dspace.mit.edu/bitstream/handle/1721.1/102957/esd-wp-2013-01.pdf?sequence=1

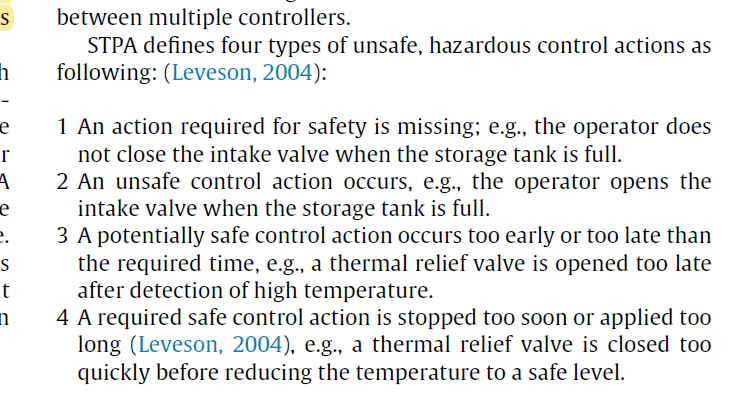

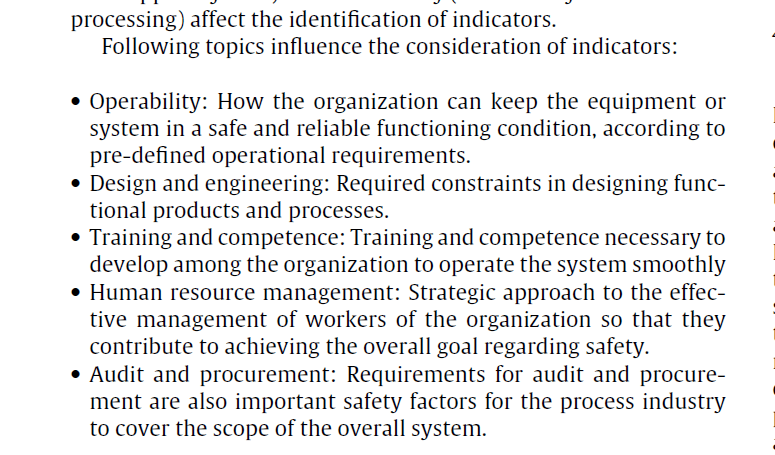

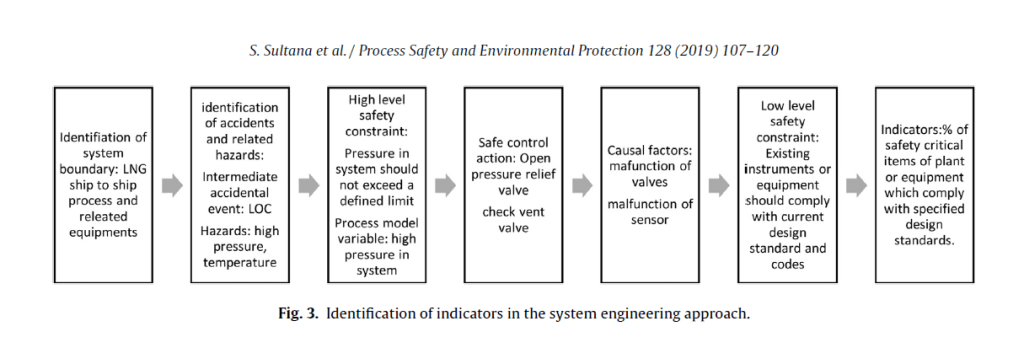

Sultana, S., Andersen, B. S., & Haugen, S. (2019). Identifying safety indicators for safety performance measurement using a system engineering approach. Process Safety and Environmental Protection, 128, 107-120. https://ntnuopen.ntnu.no/ntnu-xmlui/bitstream/handle/11250/2600400/Sultana.pdf?sequence=4

Frameworks, Logics and Other

HSE UK: https://books.hse.gov.uk/gempdf/hsg254.pdf

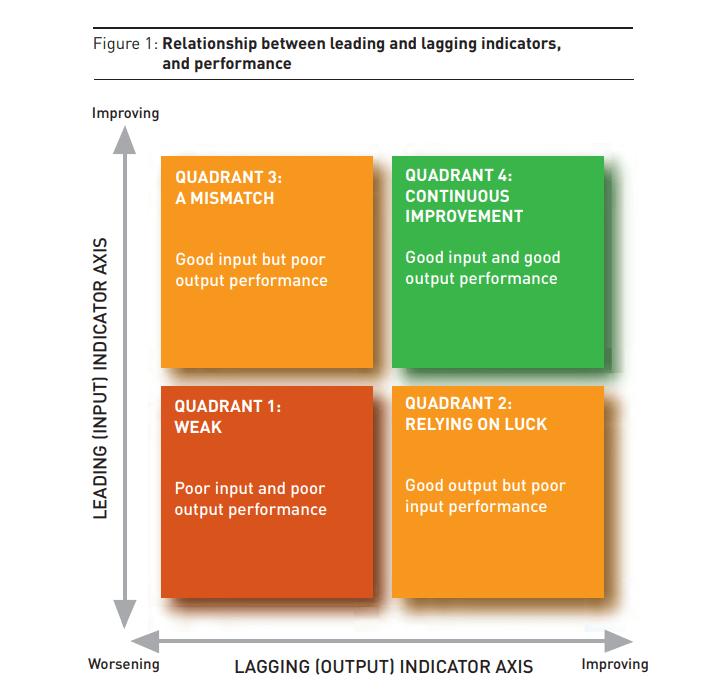

Australian Constructors Association. Lead Indicators Safety Measurement in the Construction Industry: https://www.constructors.com.au/wp-content/uploads/2019/11/Lead-Performance-Indicators-Guideline.pdf

Bayramova, A., Edwards, D. J., Roberts, C., & Rillie, I. (2023). Constructs of leading indicators: A synthesis of safety literature. Journal of safety research, 85, 469-484. https://www.sciencedirect.com/science/article/pii/S0022437523000531

Stacey, J. (2012). Overview of leading indicators for occupational health and safety in mining. International Council on Mining and Metals. https://www.icmm.com/website/publications/pdfs/health-and-safety/2012/guidance_indicators-ohs.pdf

Stacey, J. (2012). Overview of leading indicators for occupational health and safety in mining. International Council on Mining and Metals. https://www.icmm.com/website/publications/pdfs/health-and-safety/2012/guidance_indicators-ohs.pdf

Stacey, J. (2012). Overview of leading indicators for occupational health and safety in mining. International Council on Mining and Metals. https://www.icmm.com/website/publications/pdfs/health-and-safety/2012/guidance_indicators-ohs.pdf

Alruqi, W. M., & Hallowell, M. R. (2019). Critical success factors for construction safety: Review and meta-analysis of safety leading indicators. Journal of construction engineering and management, 145(3), 04019005.

RIISB. (2016). Measuring Safety Performance. https://www.rissb.com.au/wp-content/uploads/2019/03/161011_022317_Guideline-Measuring-Safety-Performance-FINAL.pdf

Haas, E. J., & Yorio, P. (2016). Exploring the state of health and safety management system performance measurement in mining organizations. Safety science, 83, 48-58. https://www.sciencedirect.com/science/article/pii/S0925753515002969?casa_token=WVSoJ8t2suUAAAAA:LlnKQ_EBlxggcokJnDrmuMVW2UKt-L_I314tw6HYj2lrzHbo-WAXgPBVZAclgjESyM7n2QdEKf1x

Khan, F., Abunada, H., John, D., & Benmosbah, T. (2010). Development of risk‐based process safety indicators. Process Safety Progress, 29(2), 133-143. https://www.academia.edu/10904688/Development_of_risk_based_process_safety_indicators

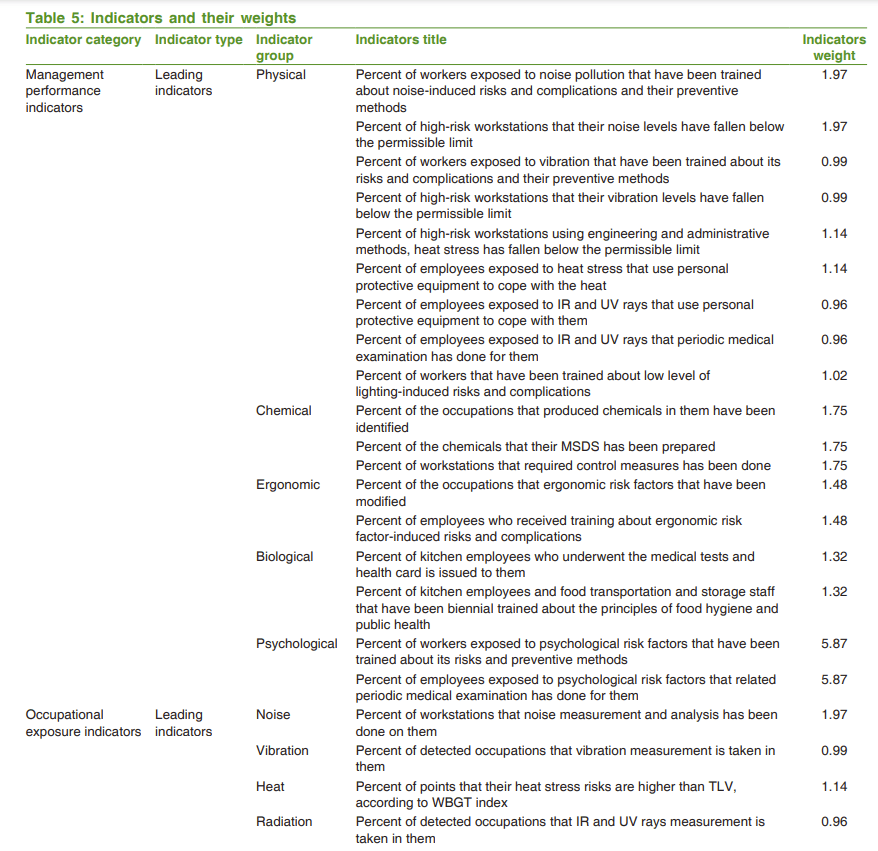

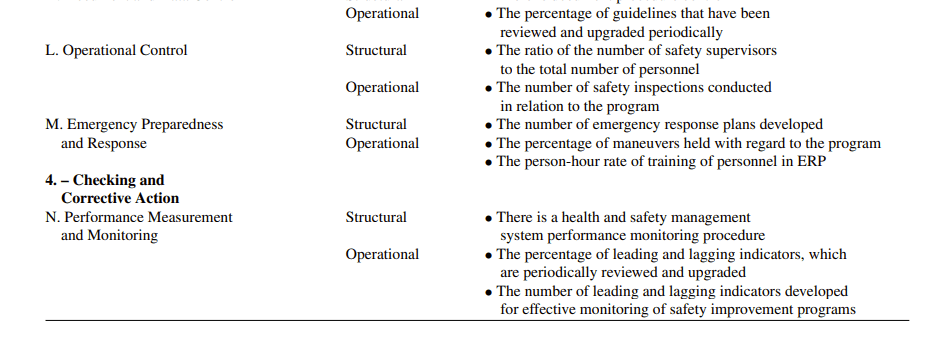

Falahati, M., Karimi, A., Mohammadfam, I., Mazloumi, A., Reza Khanteymoori, A., & Yaseri, M. (2020). Multi-dimensional model for determining the leading performance indicators of safety management systems. Work, 67(4), 959-969. https://journals.sagepub.com/doi/pdf/10.3233/WOR-203346

Table 1. The meaning of SMART criteria and their references to other sets of criteria.

| Criterion | Meaning of the criterion | Respective criteria by Kjellen (2009) | Respective criteria by Carlucci (2010) |

|---|---|---|---|

| Specific | The name of the indicator should precisely define the phenomenon under research, and should be comprehensive to all users | Indicators should be comprehended by those in charge with the responsibility of using them | Understandability and representational quality: concise and unsophisticated |

| The indicator should be appropriate for the measurement of effectiveness of the implementation of specific goals for a given action | |||

| Measurable | It should be possible to technically measure the indicator’s value based on a properly selected unit | Quantifiable and permitting statistical analyses | Comparability and consistency: the possibility for comparison of the indicator’s value between enterprises, and of the values measured at different times |

| Data for the measurement should be identifiable, and relatively readily available | Sensitive to change in environmental or behavioural conditions | ||

| The indicator should provide appropriate accuracy and repeatability of the measurement | Provide minimum variability when measuring the same conditions | Reliability: the indicator is fault-tolerant, and reliably measures what is to be measured; data for the measurement are available without high costs | |

| The indicator’s values may be used for comparisons between enterprises or organizational units | |||

| Achievable | The indicator’s values should be achievable under given conditions and in the foreseeable period of time | Cost of obtaining and using measures is consistent with the benefits | Not addressed |

| The resources (human, technical, information, etc.) necessary for the collection of data for the measurement should be sufficient | |||

| Relevanta | Measurement using the indicator should contribute to accomplishing the general objectives of a given system, process or action | Valid and representative of what is to be measured | Relevance: the indicator provides information which allows a proper adjustment of actions being carried out, or a proper forecast of the results of those actions in the future |

| The indicator should be relevant to the operation of an enterprise or organizational unit, as well as for its users | |||

| The results of the measurement using the indicator should be appropriate for fulfilling relevant requirements concerning documentation of the actions | |||

| Time-bound | It should be possible to determine the period in which a given value of the indicator may be achieved | Not addressed | Not addressed |

| The time for achieving a given value of the indicator may be divided into successive stages | |||

Podgórski, D. (2015). Measuring operational performance of OSH management system–A demonstration of AHP-based selection of leading key performance indicators. Safety science, 73, 146-166. https://www.sciencedirect.com/science/article/pii/S0925753514003063

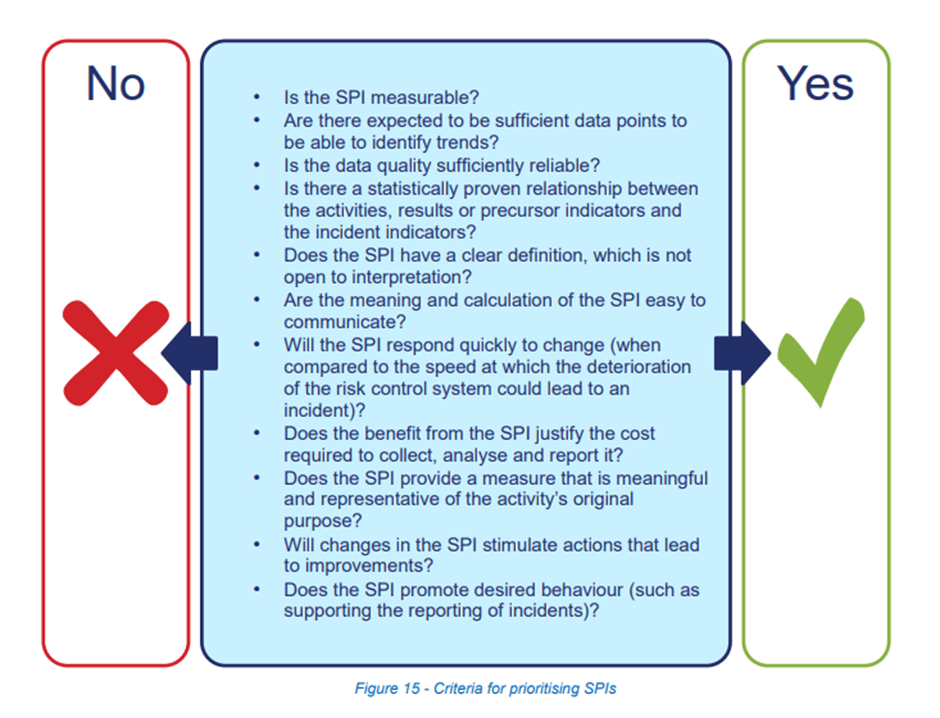

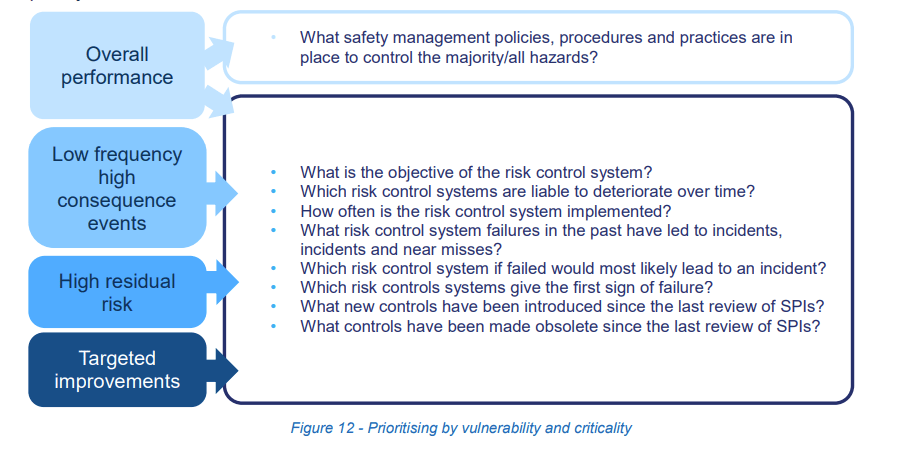

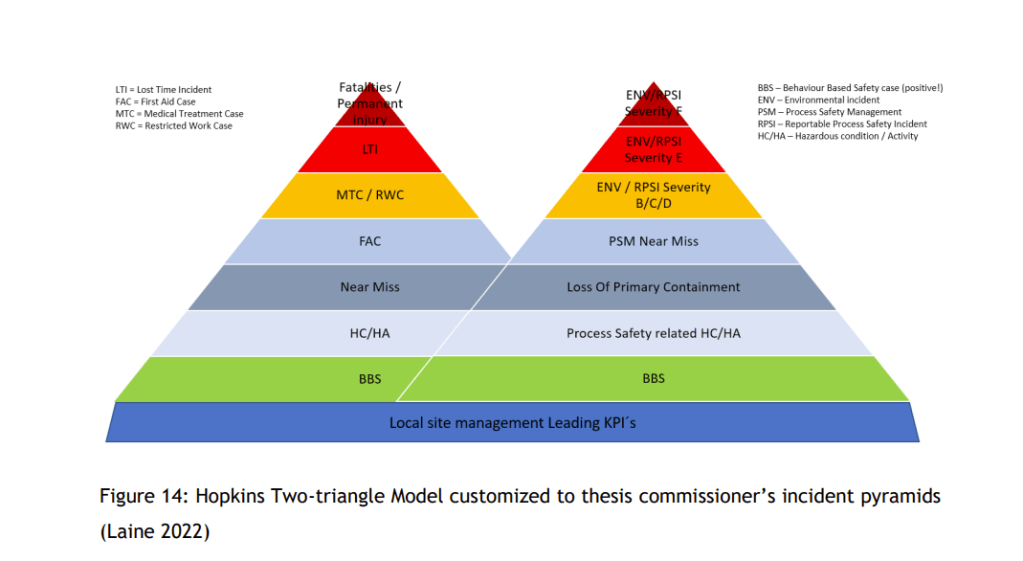

Laine, J. (2022). Developing Process Safety Performance Indicators and Process Safety Metrics in Chemical Industry. https://www.theseus.fi/bitstream/handle/10024/783019/Laine_Jussi.pdf?sequence=2

Table 1. Summary of Existing Performance Metrics.

| Existing Performance Metrics | Definition | Examples | References | |

|---|---|---|---|---|

| Injury Rates | First Aid Rate | Number of first aid injuries per 200,000 full-time equivalent worker-hours. | – | (Huang and Hinze, 2006, U.S. Department of Labor, 2004) |

| TRIR | Number of recordable incidents per 200,000 full-time equivalent worker-hours. | – | (U.S. Bureau of Labor Statistics., 2020, U.S. Department of Labor, 2004, U.S. Department of Labor, 2010 | |

| DART | Number of recordable incidents that resulted in days away from work, restricted work duty, or job transfer per 200,000 full-time equivalent worker-hours. | – | (U.S. Department of Labor, 2004) | |

| Fatality Rate | Number of fatal work injuries per 100,000 full-time equivalent worker-hours. | – | (Raheem and Hinze, 2014, U.S. Bureau of Labor Statistics., 2020) | |

| Near Miss Incident Rates | The frequency of incidents where no injury was sustained, but with a slight change in the circumstances such the injury would have been sustained. | Fallen tool but did not strike a worker, worker in excavator boom radius, worker standing on the rails of a bucket lift, etc. | (Cambraia et al., 2010, Oswald et al., 2018, Sarkar et al., 2019, Teizer and Cheng, 2015; Wu, Gibb, et al., 2010) | |

| Safety Leading Indicators | The frequency of injury prevention activities. | Number of audits, Pre-job meetings, Drug tests, Owner involvement, Hazard and accident analysis, Incentives, etc. | (M. R. Hallowell et al., 2013, Hinze et al., 2013a, Lingard et al., 2017, Manjourides and Dennerlein, 2019) | |

| Precursor Analysis Scores | The trends in the status of human resources as assessed through fields safety engagements on site. | Schedule pressure, Fatigue, Inexperience of worker/crew with the task, language barrier, limited safety supervision, etc. | (Alexander et al., 2017a, Alexander et al., 2017b) | |

| Safety Climate | The status of employee perceptions on the safety management system. | Management’s commitment to safety, supervisor’s role, training, etc. | (Al-Bayati et al., 2019, Alruqi and Hallowell, 2019, Choudhry and Fang, 2008, Hon et al., 2014, Nadhim et al., 2018) | |

Table 4. Construction Safety Performance Metric Ratings under Evidence-based Evaluation Criteria.

| Construction Safety Performance Metrics | Evidence-based Evaluation Criteria | ||

|---|---|---|---|

| Predictive | Valid | Objective | |

| First Aid Rates | 0.5 | 1.0 | 1.0 |

| TRIR | 0.0 | 0.0 | 1.0 |

| DART | 0.0 | 0.0 | 1.0 |

| Fatality Rates | 0.5 | 0.0 | 1.0 |

| Near Miss Incident Rates | 0.5 | 1.0 | 0.5 |

| Leading Indicators | 1.0 | 1.0 | 1.0 |

| Precursor Analysis Scores | 1.0 | 1.0 | 0.0 |

| Safety Climate | 1.0 | 1.0 | 0.0 |

Erkal, E. D. O., Hallowell, M. R., & Bhandari, S. (2023). Formal evaluation of construction safety performance metrics and a case for a balanced approach. Journal of safety research, 85, 380-390. https://www.sciencedirect.com/science/article/pii/S0022437523000439?casa_token=O4FHW42dgsIAAAAA:6Fo6K_eCjm7_aEzUZbdh6FU3MScPYlUaaVTIHCl18w8BciyYul95cSpN6R3m9Q7MK6v51jCf70Fq

Wang, M., Mentzer, R. A., Gao, X., Richardson, J., & Mannan, M. S. (2013). Normalization of process safety lagging metrics. Process Safety Progress, 32(4), 337-345.

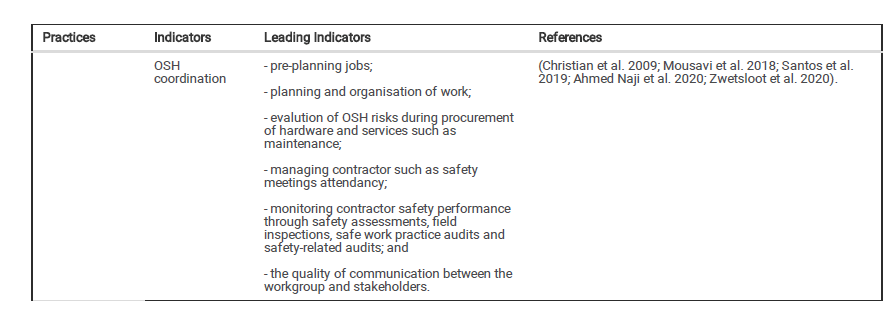

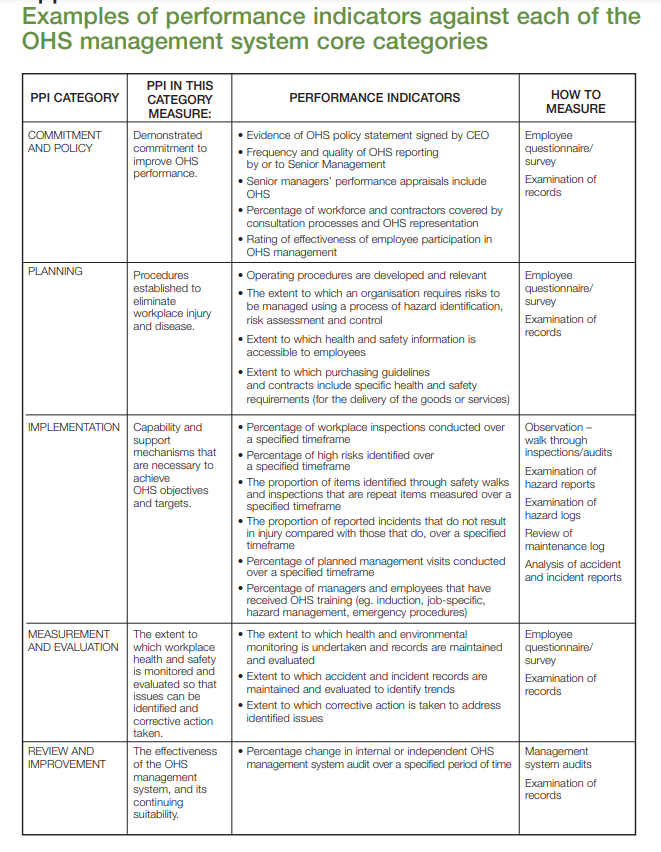

Safety, A., & Council, C. (2005). Guidance on the Use of Positive Performance Indicators to Improve Workplace Health and Safety. Safe Work Australia, Commonwealth of Australia: Canberra, Australia. https://www.safeworkaustralia.gov.au/system/files/documents/1702/guidanceonuseofppis_2005_pdf.pdf

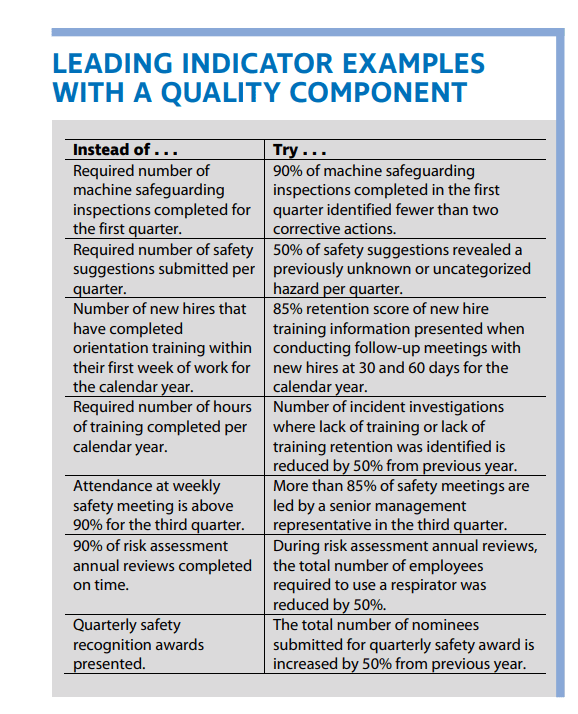

Indicator Examples

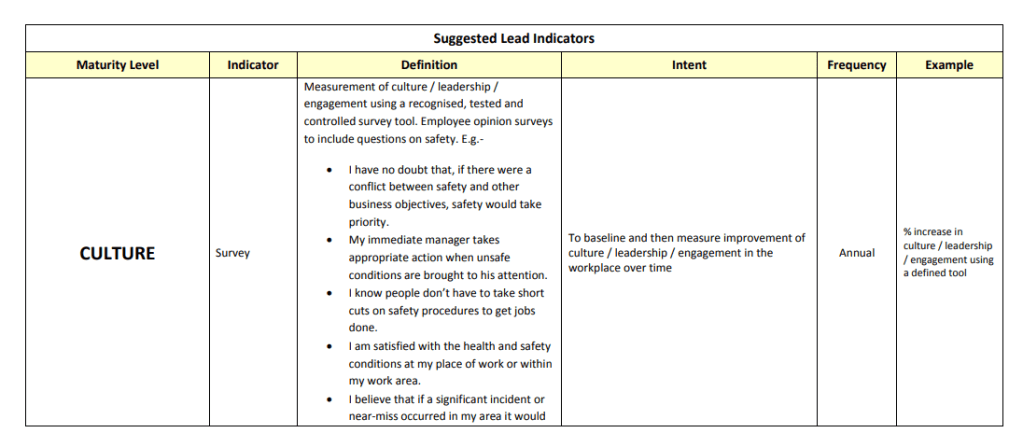

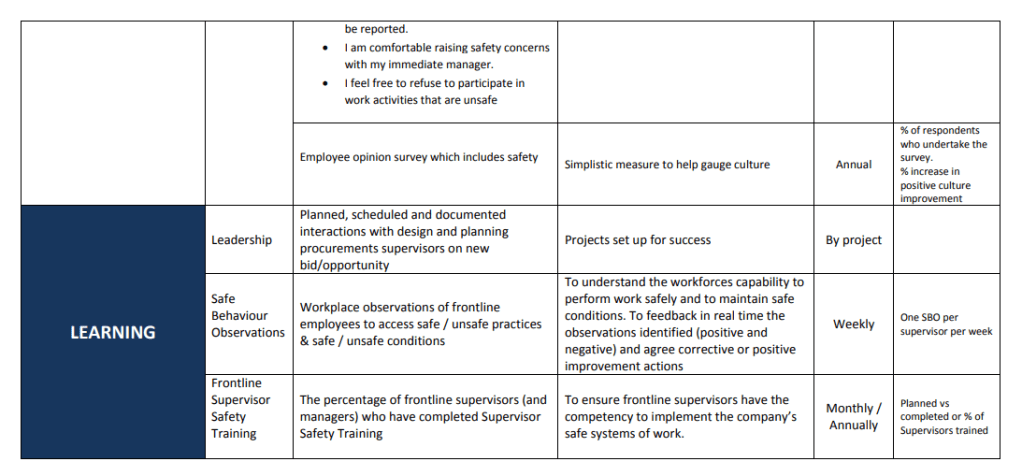

Australian Constructors Association. Lead Indicators Safety Measurement in the Construction Industry: https://www.constructors.com.au/wp-content/uploads/2019/11/Lead-Performance-Indicators-Guideline.pdf

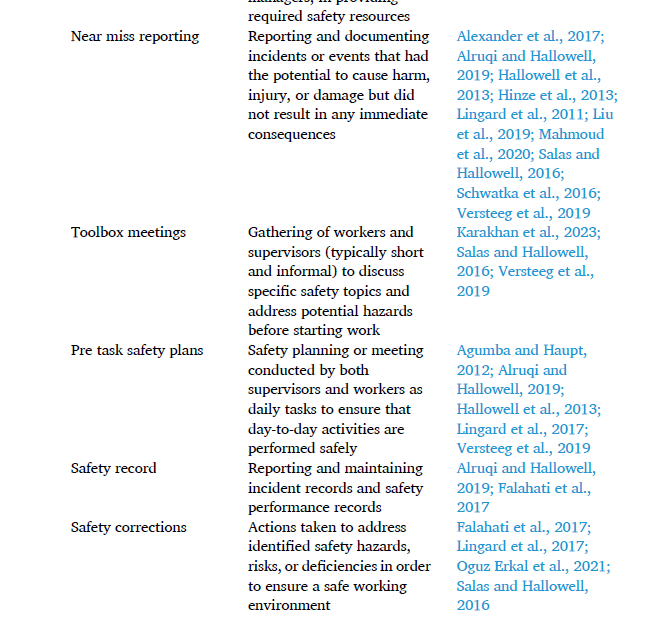

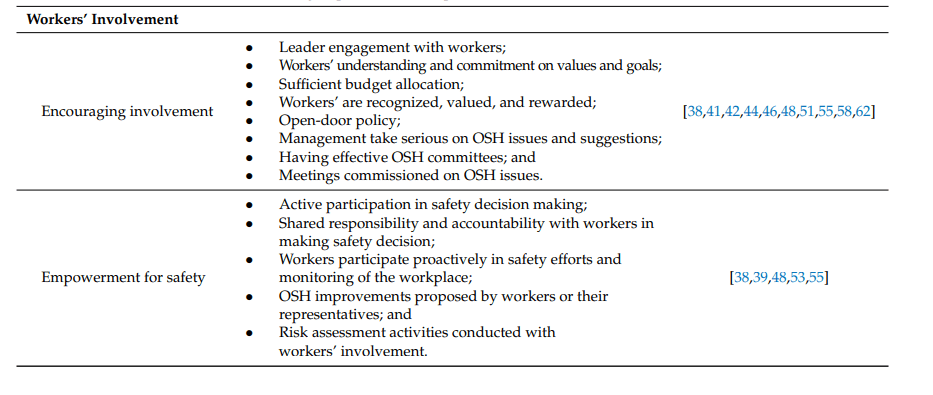

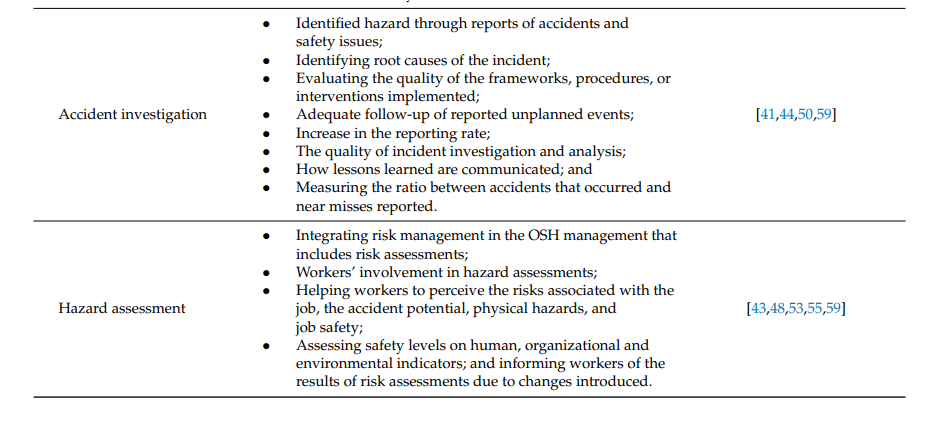

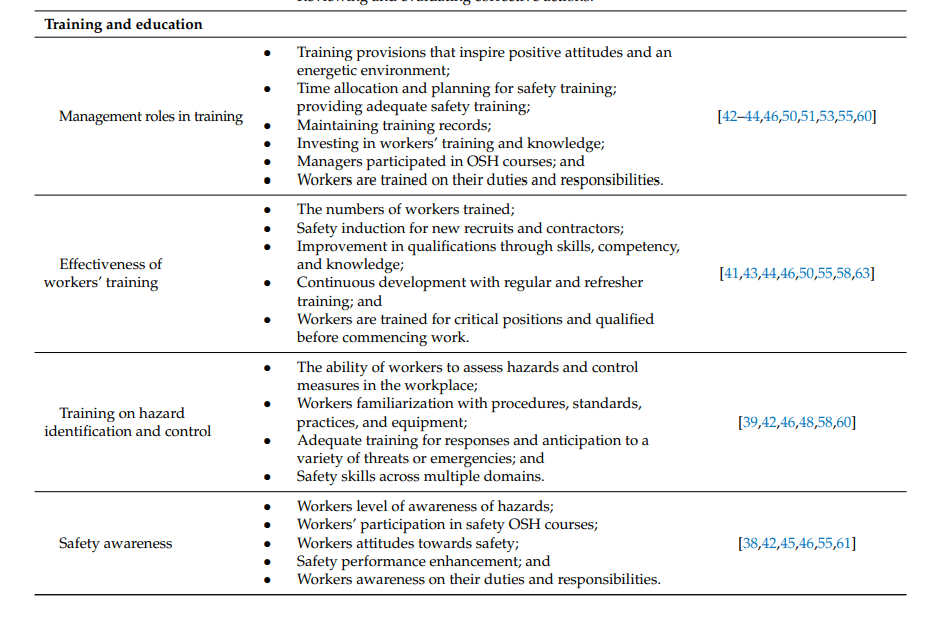

Xu et al. Safety leading indicators in construction: a systematic review. Safety Science: https://discovery.ucl.ac.uk/id/eprint/10124688/7/Xu_Author%20Accepted%20Version.pdf

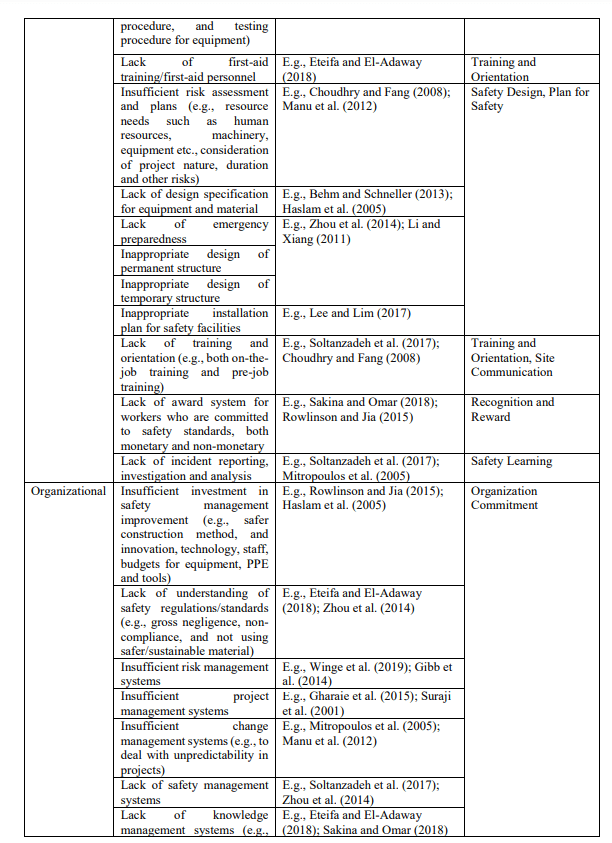

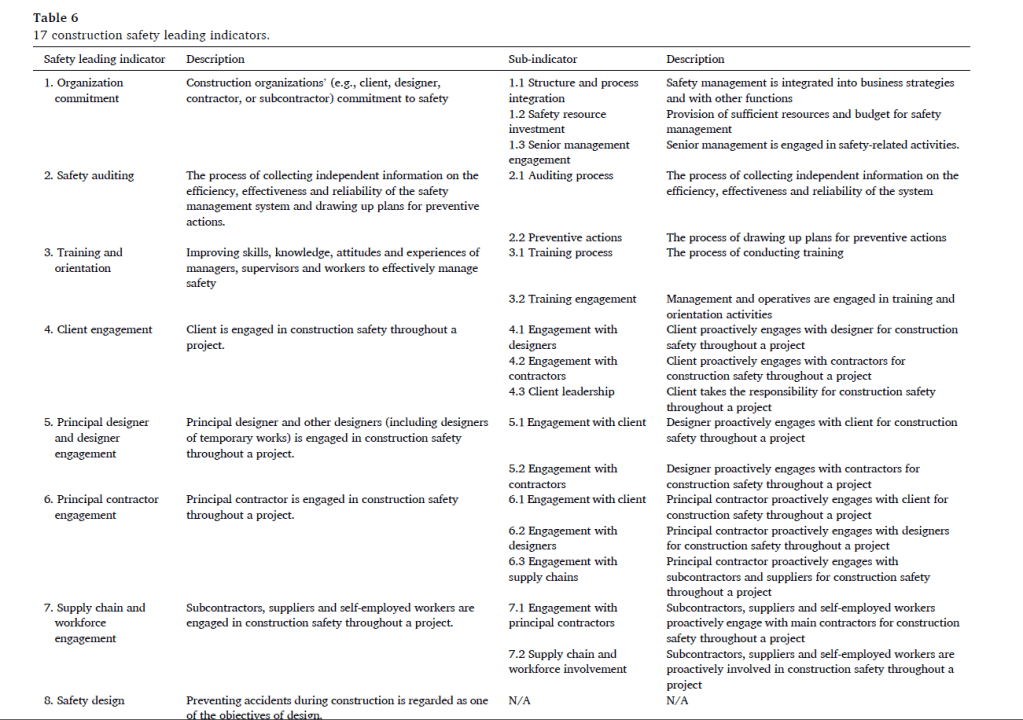

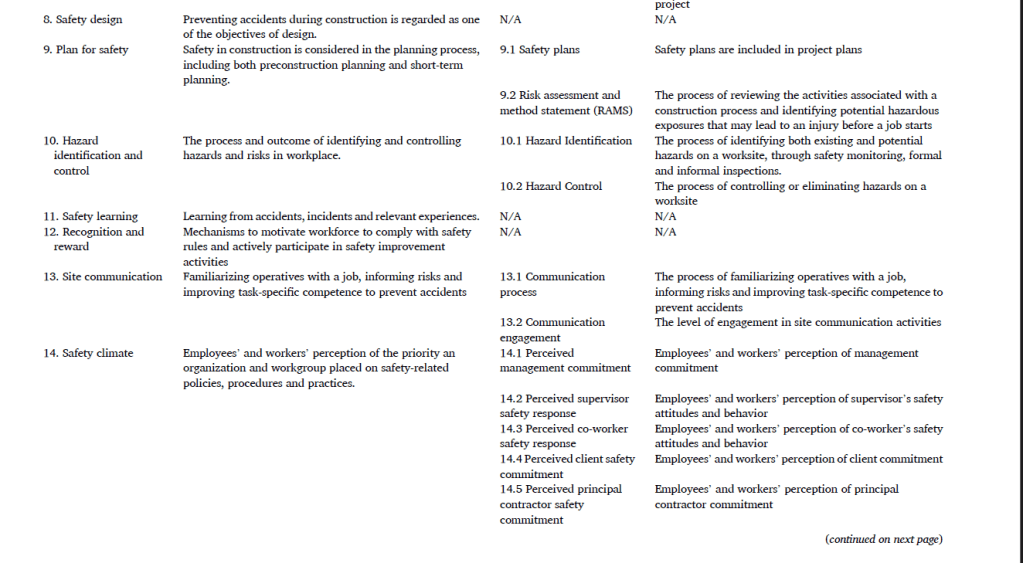

Xu et al. Safety leading indicators in construction: a systematic review. Safety Science: https://discovery.ucl.ac.uk/id/eprint/10124688/7/Xu_Author%20Accepted%20Version.pdf

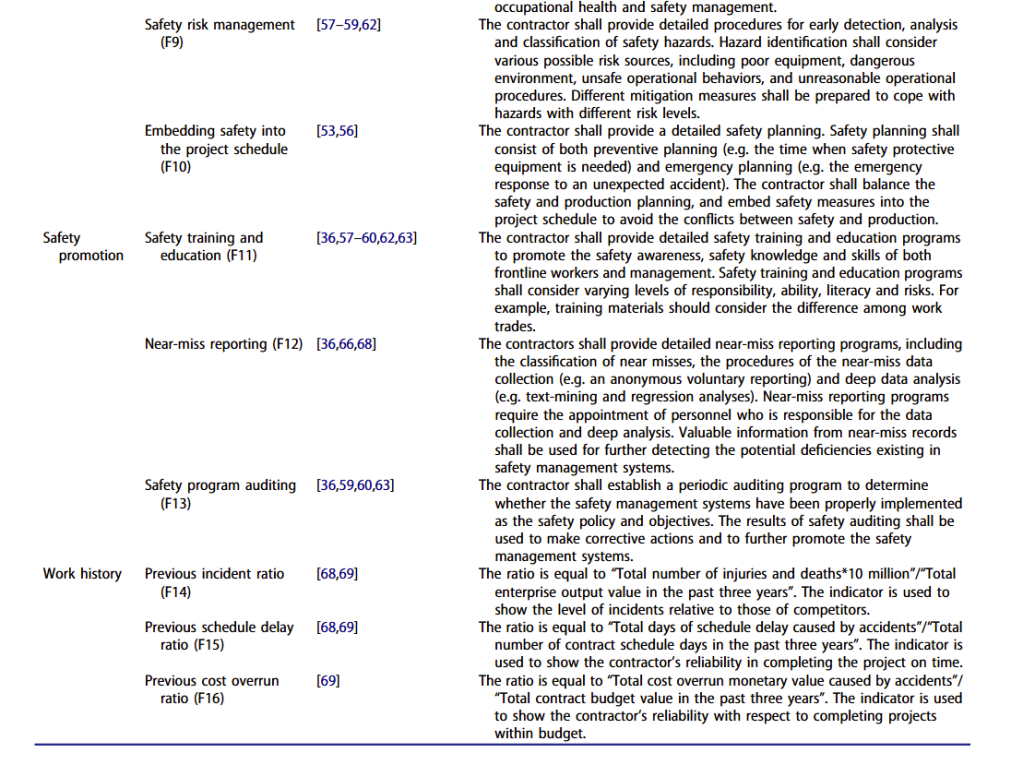

Guo, B. H., & Yiu, T. W. (2016). Developing leading indicators to monitor the safety conditions of construction projects. Journal of management in engineering, 32(1), 04015016. https://www.academia.edu/download/41620634/Developing_Leading_Indicators_to_Monitor20160127-28594-1vzn0o5.pdf

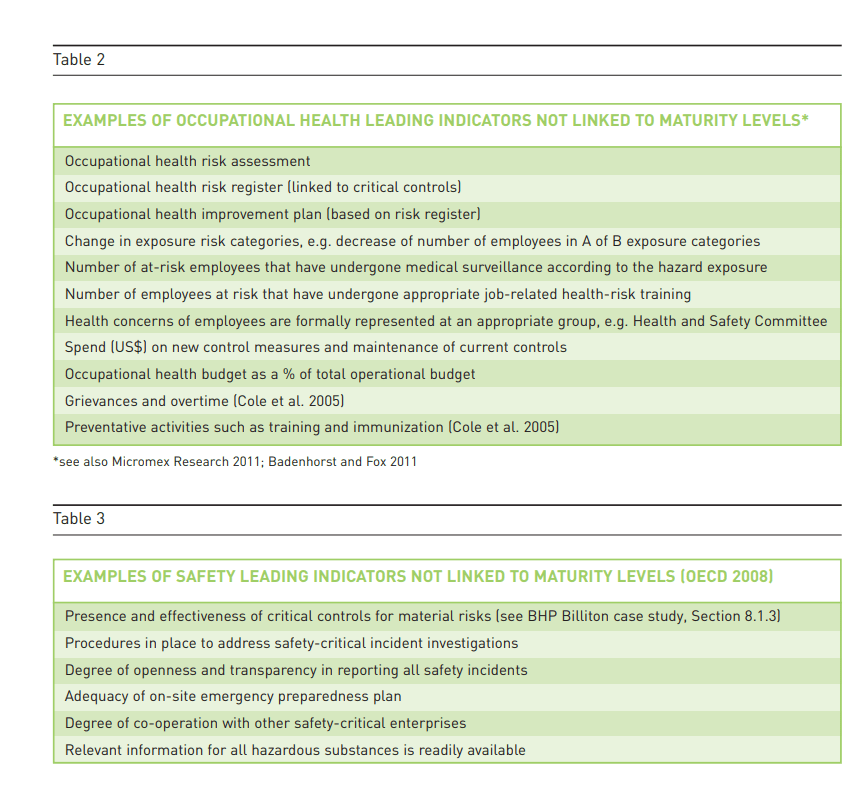

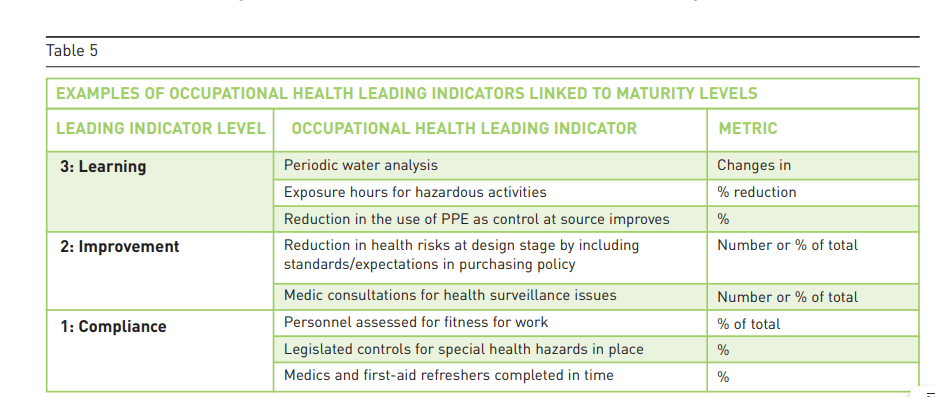

Stacey, J. (2012). Overview of leading indicators for occupational health and safety in mining. International Council on Mining and Metals. https://www.icmm.com/website/publications/pdfs/health-and-safety/2012/guidance_indicators-ohs.pdf

Hallowell, M. R., Hinze, J. W., Baud, K. C., & Wehle, A. (2013). Proactive construction safety control: Measuring, monitoring, and responding to safety leading indicators. Journal of construction engineering and management, 139(10), 04013010. https://dralavipour.com/storage/app/media/course/applied-resource/documents/12.%20proactive_construction_safety.pdf

Alruqi, W. M., & Hallowell, M. R. (2019). Critical success factors for construction safety: Review and meta-analysis of safety leading indicators. Journal of construction engineering and management, 145(3), 04019005.

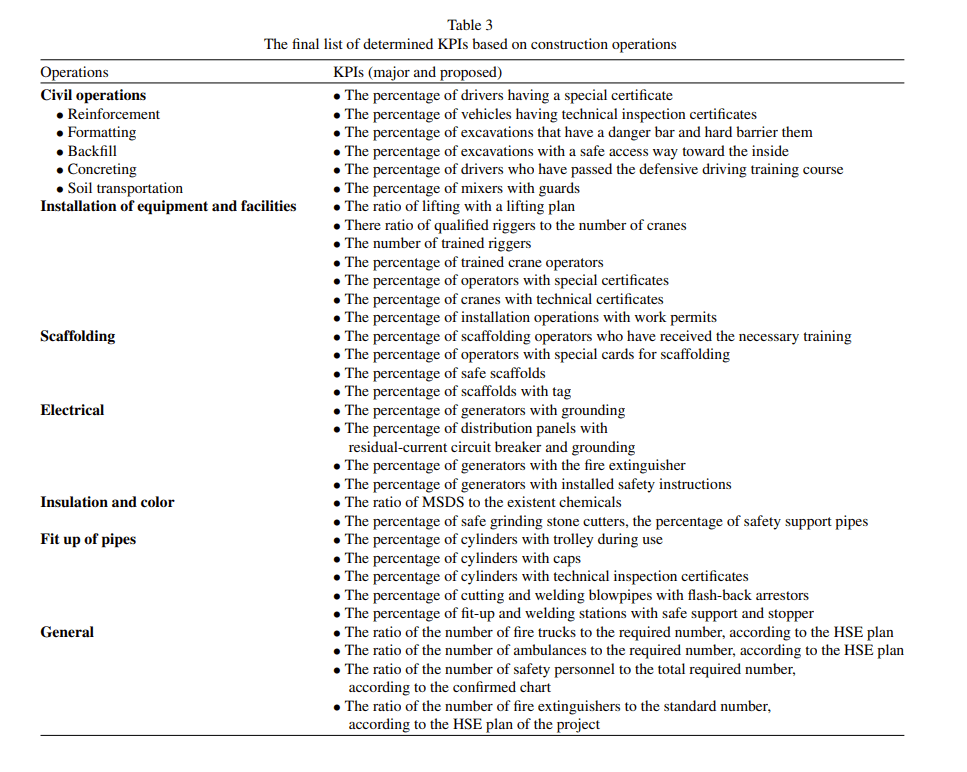

Golabchi, H., Abellanosa, A. D., Lefsrud, L., Pereira, E., & Mohamed, Y. (2024). A comprehensive systematic review of safety leading indicators in construction. Safety science, 172, 106433.

Shaikh, A. Y., Osei‐Kyei, R., & Hardie, M. (2021). A critical analysis of safety performance indicators in construction. International Journal of Building Pathology and Adaptation, 39(3), 547-580. https://www.researchgate.net/profile/Aziz-Shaikh-2/publication/343669634_A_critical_analysis_of_safety_performance_indicators_in_construction/links/5f8ae3f8458515b7cf85420c/A-critical-analysis-of-safety-performance-indicators-in-construction.pdf

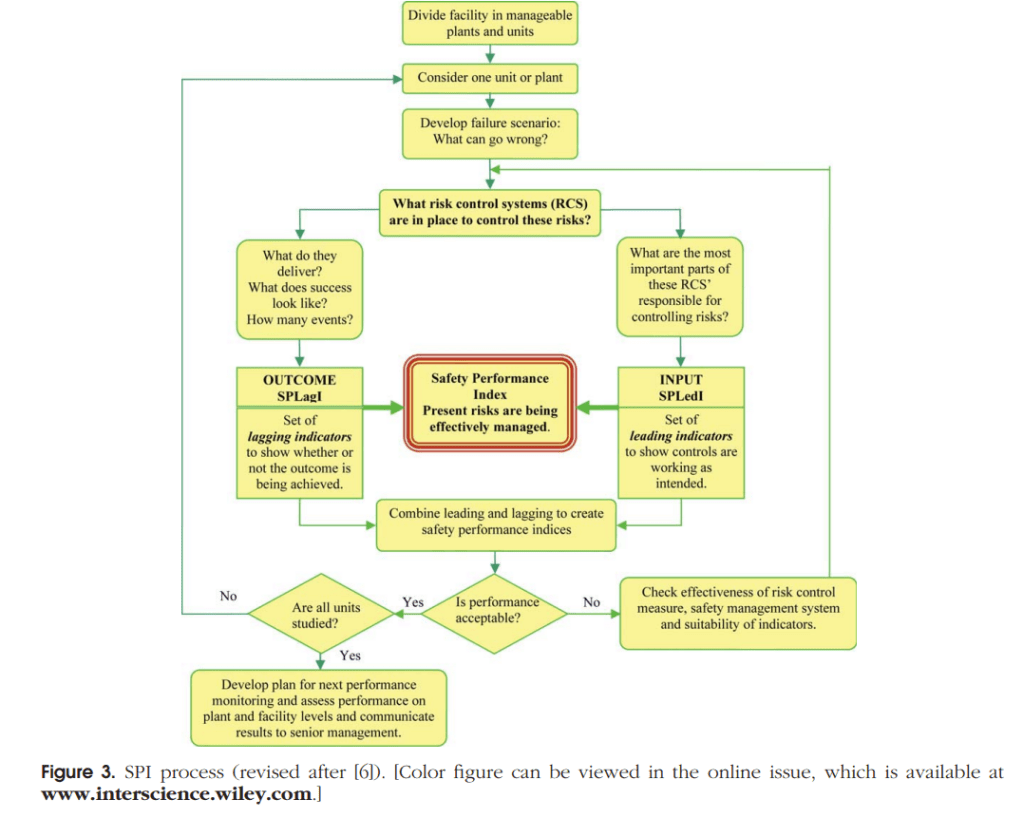

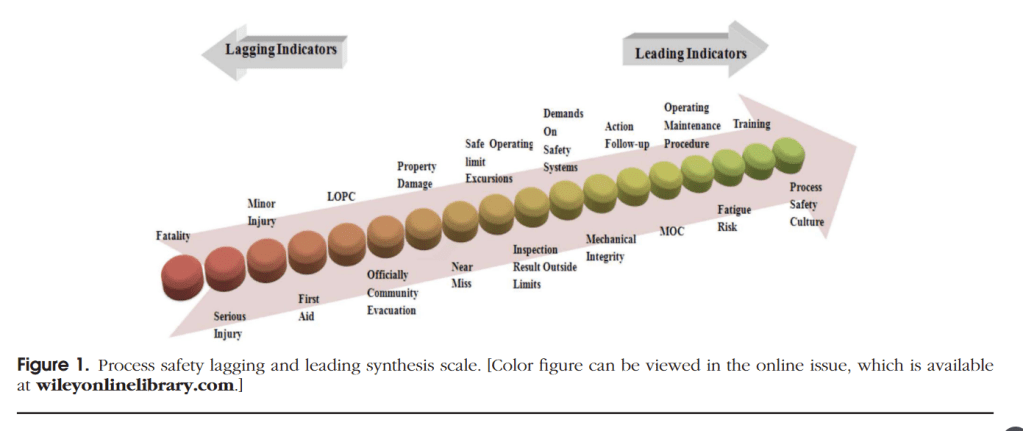

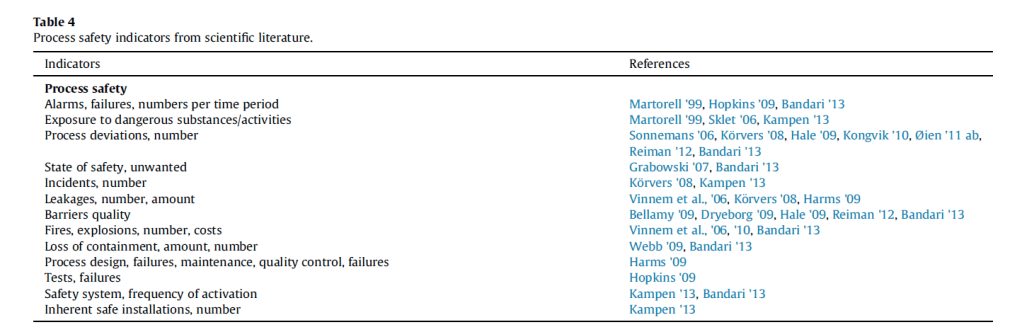

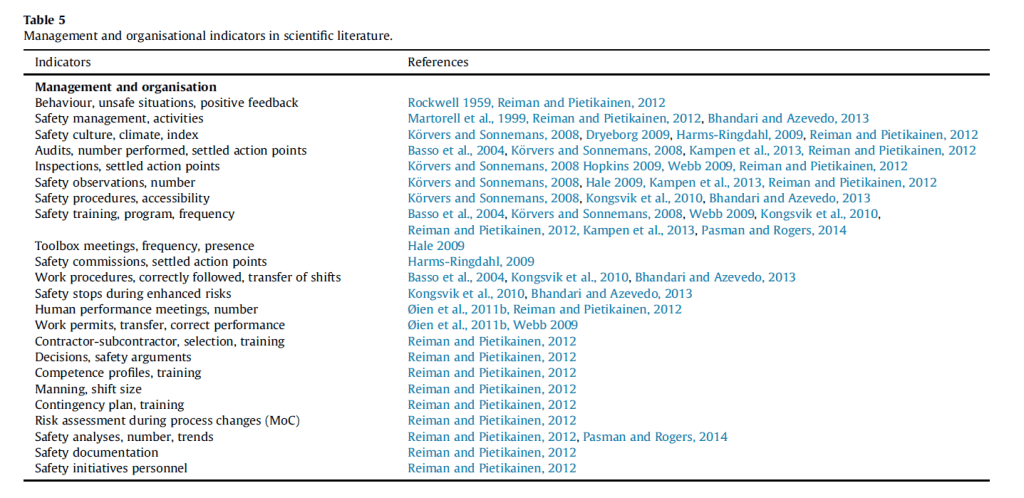

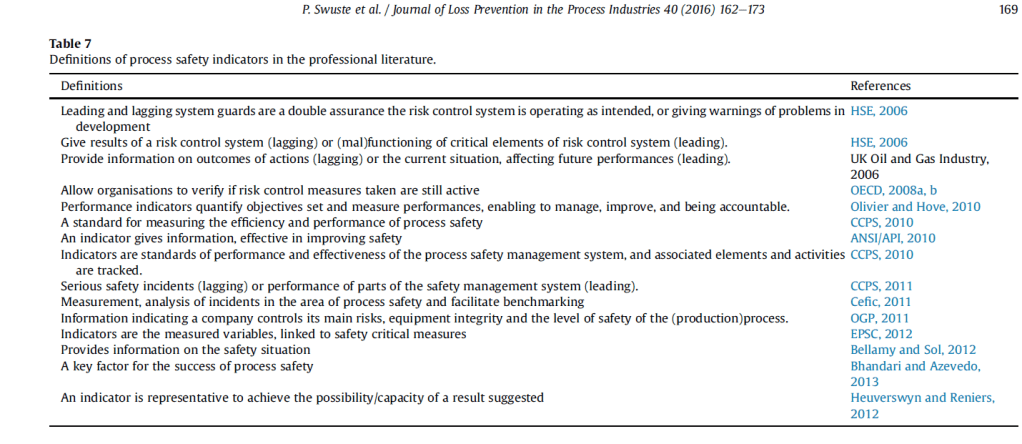

Swuste, P., Theunissen, J., Schmitz, P., Reniers, G., & Blokland, P. (2016). Process safety indicators, a review of literature. Journal of Loss Prevention in the Process Industries, 40, 162-173. https://repository.uantwerpen.be/docman/irua/1d3c6e/129952_2017_12_30.pdf

Xu, J., Cheung, C., Manu, P., Ejohwomu, O., & Too, J. (2023). Implementing safety leading indicators in construction: Toward a proactive approach to safety management. Safety science, 157, 105929. https://www.sciencedirect.com/science/article/pii/S0925753522002685

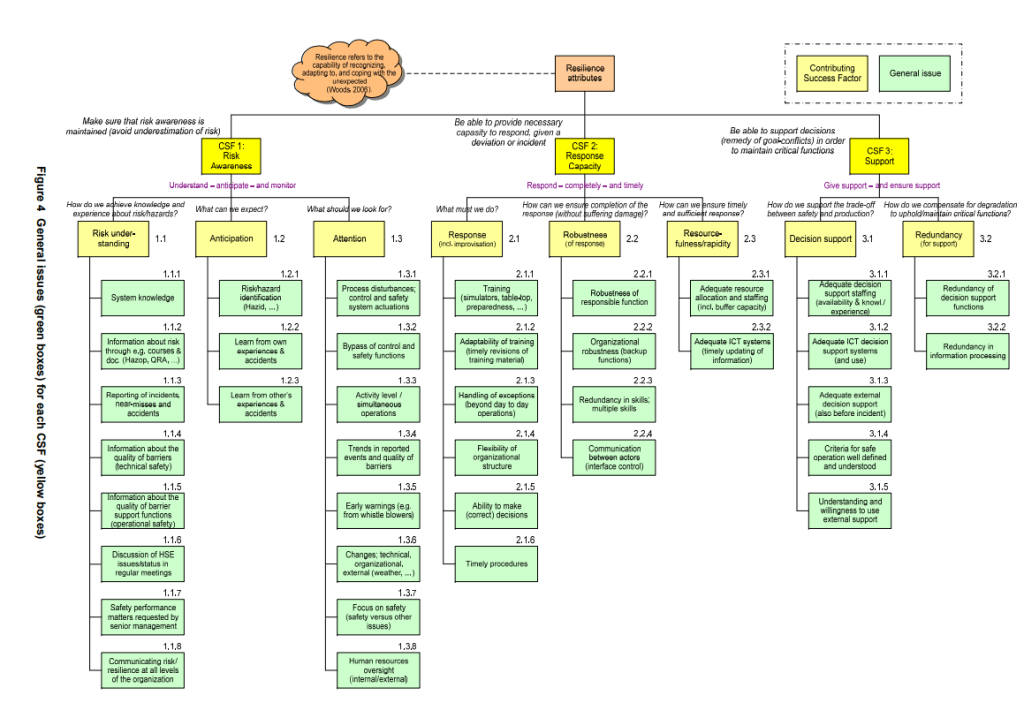

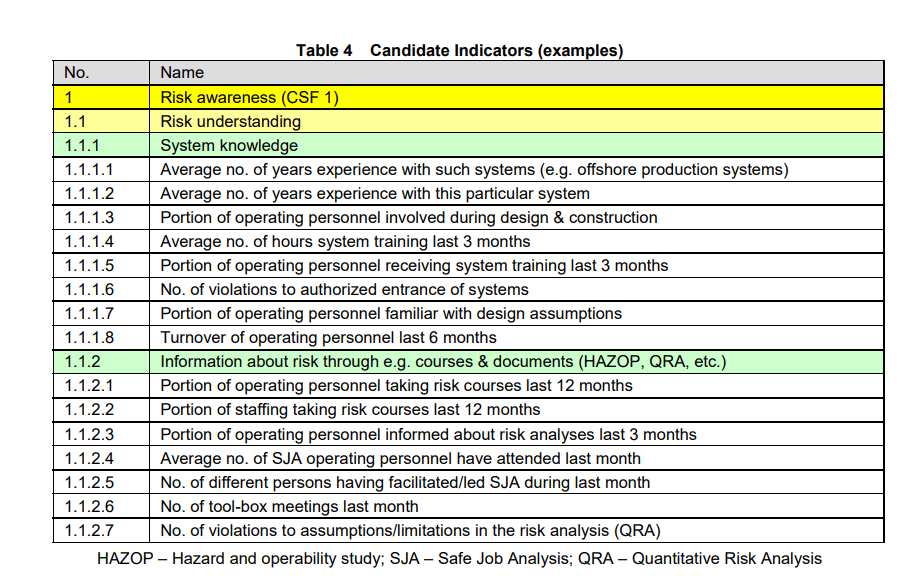

Øien, K., Utne, I. B., Tinmannsvik, R. K., & Massaiu, S. (2011). Building safety indicators: Part 2–application, practices and results. Safety science, 49(2), 162-171.

Reiman, T., & Pietikäinen, E. (2010). Indicators of safety culture-selection and utilization of leading safety performance indicators. https://www.osti.gov/etdeweb/servlets/purl/979791

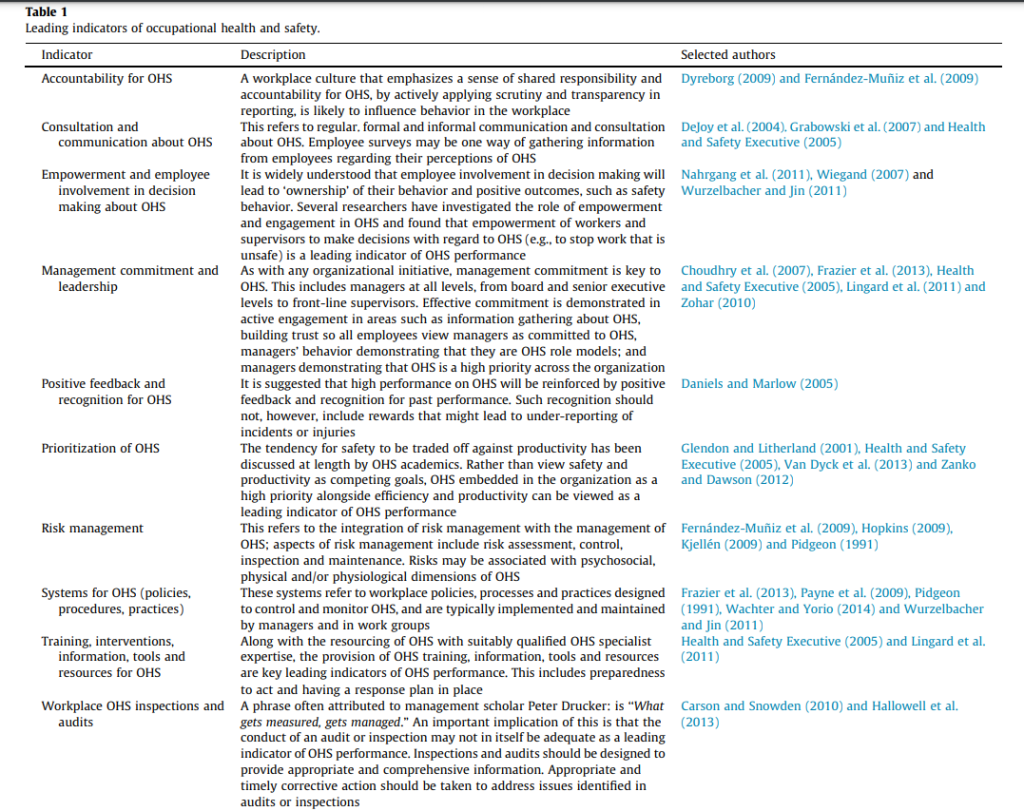

Shea, T., De Cieri, H., Donohue, R., Cooper, B., & Sheehan, C. (2016). Leading indicators of occupational health and safety: An employee and workplace level validation study. Safety science, 85, 293-304.

Ranasinghe, U., Jefferies, M., Davis, P., & Pillay, M. (2020). Resilience engineering indicators and safety management: A systematic review. Safety and Health at Work, 11(2), 127-135. https://www.sciencedirect.com/science/article/pii/S2093791120302663

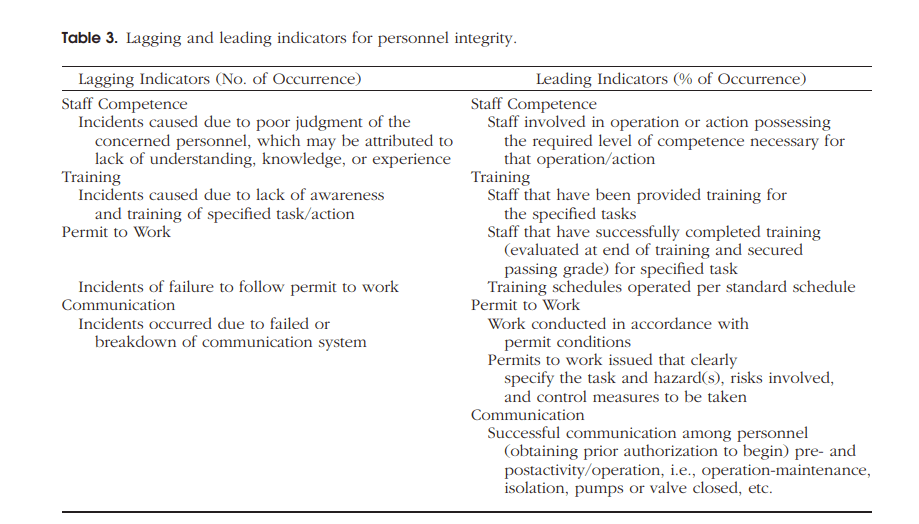

Karimi, A., Abbasi, M., Zokaei, M., & Falahati, M. (2021). Development of leading indicators for the assessment of occupational health performance using Reason’s Swiss cheese model. Journal of education and health promotion, 10(1), 158. https://journals.lww.com/jehp/_layouts/15/oaks.journals/downloadpdf.aspx?an=01679914-202110000-00149

Table 5 shows the final set of the ISSA proactive leading indicators for SHW at work.

Table 5. International Social Security Association’s (ISSA) proactive leading indicators for safety, health and wellbeing (SHW) at work.

| Rule No. 1: Take leadership – demonstrate commitment | |

| Indicator No. 1.1 Visible leadership commitment | Through visible leadership commitment and being exemplary role models, leaders demonstrate their commitment to SHW, and actively promote and support SHW improvement processes and the development of a prevention culture. |

| Indicator No. 1.2 Competent leadership | Committed and competent SHW leadership is essential to drive the development processes of VISION ZERO. Such leaders are intrinsically motivated to improve SHW and promote SHW as personal and organizational core values. Leaders then regard SHW as integrated parts of business processes, and support processes of continual improvement of SHW, while creating a strong prevention culture. |

| Rule No. 2: Identify hazards – control risks | |

| Indicator No. 2.1 Evaluating risk management | Evaluation of the effectiveness of SHW risk management shows leadership focus and commitment to improving SHW, and stimulates active participation and influence of workers. It allows leaders and workers to improve the effectiveness and sustainability of SHW promotion measures as an integrated part of business. In addition, it allows for organizational learning and continuous development. |

| Indicator No. 2.2 Learning from unplanned events | Learning from unplanned events (incidents, events, cases) is necessary to prevent similar undesirable events from reoccurring, and to create a culture of SHW prevention and learning. Adequate follow-up of reported unplanned events will increase reporting and learning. |

| Rule No. 3: Define targets – develop programmes | |

| Indicator No. 3.1 Workplace and job inductions | Integrating SHW in induction (on-boarding) processes demonstrates that SHW are an integrated part of each job and each business process. SHW are an essential part of leaders’ and workers’ new job in a workplace. It can be both a formal and informal way of welcoming new personnel to an organization, group and/or job function, and highlights SHW purpose, values and goals. |

| Indicator No. 3.2 Evaluating targeted programmes | Evaluating targeted programmes (e.g. temporary campaigns) that integrate SHW in work processes helps to verify that they are implemented as intended, and that the improvement goals for SHW are met. |

| Rule No. 4: Ensure a safe and healthy system – be well organized | |

| Indicator No. 4.1 Pre-work briefings | Integrating SHW in pre-work briefings allows leaders and workers to identify context specific hazards, risks and prevention measures. This shows leadership focus and commitment to SHW, and a commitment to stimulating the active participation and influence of workers. |

| Indicator No. 4.2 Planning and organization of work | Planning and organization of work are essential for the success of every organization and for ensuring SHW. This is because planning can make an organization competitive and efficient. Several issues need to be considered in effective planning and work organization in order to promote SHW. Good planning and work organization promote good morale and a healthy organizational culture. |

| Rule No. 5: Ensure SHW in machines, equipment and workplaces | |

| Indicator No. 5.1 Innovation and change | Technological, organizational and personnel changes occur frequently in organizations. Instead of assessing SHW risk after the changes, these changes should be considered proactively, and to utilize innovation to improve SHW right from the start in the design phase. |

| Indicator No. 5.2 Procurement | The indicator aims to trigger the systematic use of procurement for SHW improvement. Procurement, particularly of hardware, can determine SHW risks for a long period, while procurement of services such as maintenance, is often associated with increased SHW risks. |

| Rule No. 6: Improve qualifications – develop competence | |

| Indicator No. 6.1 Initial training | Competence is key to ensuring good SHW. Being proactive requires training/qualifying leaders and workers in advance, before they start their job. It also shows that no job or task should be carried out without the relevant SHW competences, and that SHW are an integrated part of any job or profession. |

| Indicator No. 6.2 Refresher training | Developing SHW competence should be an aspect of continuous professional development. Refresher training ensures that leaders and workers’ knowledge and skills on SHW remain up to date and include new SHW insights. |

| Rule No. 7: Invest in people – motivate by participation | |

| Indicator No. 7.1 Suggestions for improvement | In the development of a prevention culture and the active involvement of workers, it is important that suggestions of workers for SHW improvements are welcomed and are taken seriously. This will stimulate workers’ active commitment to SHW and demonstrates their leaders’ commitment to improving SHW. |

| Indicator No. 7.2 Recognition and reward | Providing timely, proactive and relevant recognition and reward for excellent SHW performance to both leaders and workers is essential for fostering a SHW culture that is based on trust, respect, participation and cooperation. |

Zwetsloot, G., Leka, S., Kines, P., & Jain, A. (2020). Vision zero: Developing proactive leading indicators for safety, health and wellbeing at work. Safety Science, 130, 104890. https://www.sciencedirect.com/science/article/pii/S0925753520302873

Haas, E. J., & Yorio, P. (2016). Exploring the state of health and safety management system performance measurement in mining organizations. Safety science, 83, 48-58. https://www.sciencedirect.com/science/article/pii/S0925753515002969?casa_token=WVSoJ8t2suUAAAAA:LlnKQ_EBlxggcokJnDrmuMVW2UKt-L_I314tw6HYj2lrzHbo-WAXgPBVZAclgjESyM7n2QdEKf1x

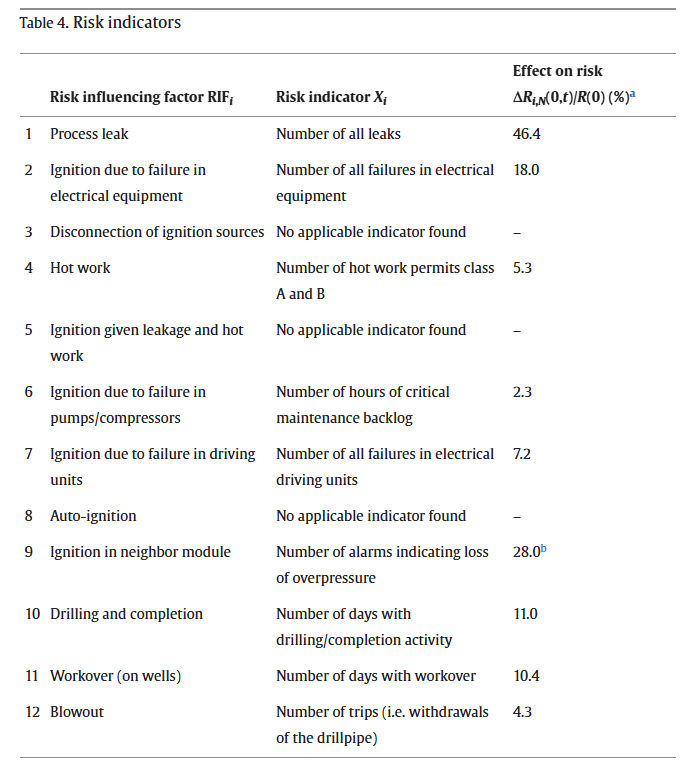

Øien, K. (2001). Risk indicators as a tool for risk control. Reliability Engineering & System Safety, 74(2), 129-145. https://www.sciencedirect.com/science/article/pii/S0951832001000679?casa_token=BVpXn5QSqGwAAAAA:eW2sncB3HZrUSCN53mc5a6F4Ei0QSwfWGRXa8GoNqNJ3VOsNsZWMaIZrqlM0ce_8leLtQUXIKriB

Khan, F., Abunada, H., John, D., & Benmosbah, T. (2010). Development of risk‐based process safety indicators. Process Safety Progress, 29(2), 133-143. https://www.academia.edu/10904688/Development_of_risk_based_process_safety_indicators

Falahati, M., Karimi, A., Mohammadfam, I., Mazloumi, A., Reza Khanteymoori, A., & Yaseri, M. (2020). Multi-dimensional model for determining the leading performance indicators of safety management systems. Work, 67(4), 959-969. https://journals.sagepub.com/doi/pdf/10.3233/WOR-203346

Table 5. The final set of KPIs assigned to individual OSH MS components.

| OSH MS component | KPIs (maina and alternative) |

|---|---|

| Policy | |

| A. OSH policy | A1: Number of OSH policy reviews and updates carried out by top management A2: Percentage of workers declaring good knowledge of OSH policy A3: Number of safety walkthroughs performed by top managers |

| B. Workers’ participation | B1: Number of OSH improvements proposed by workers B2: Number of OSH Commission meetings on regular OSH issues |

| Organizing | |

| C. Responsibilities and accountability | C1: Percentage of work posts with defined OSH responsibilities and duties |

| D. Delivering OSH training | D1: Percentage of workers participating in OSH refresher courses D2: Number of hours for OSH training per person |

| E. Evaluation and improvement of OSH training programmes | E1: Percentage of OSH training courses reviewed and improved for their quality and effectiveness |

| F. OSH MS documentation | F1: Percentage of OSH MS procedures improved due to corrective actions F2: Percentage of workers participating in trainings on OSH MS structure, procedures, etc. |

| G. Communication | G1: Number of meetings conducted by managers to inform workers on OSH issues G2: Rating of the effectiveness of OSH communication via workforce survey G3: Number of issues of company’s OSH bulletin or other internal OSH publications |

| Planning and implementation | |

| H. OSH goals and improvement plans | H1: Number of measurable OSH improvement goals established in the enterprise H2: Percentage of tasks in OSH improvement plans verified and accepted with regard to the quality and effectiveness |

| I. Risk assessment processes | I1: Percentage of periodically verified risk assessment processes with regard to their validity and correctness of risk control measures applied |

| J. Implementation of risk control measures | J1: Percentage of workers informed on risk levels and risk control measures applied J2: Number of risk control measure implementations with hierarchy of measures considered |

| K. Management of change | K1: Number of analyses of impact on OSH carried out with regard to changes in OSH regulations, technologies and knowledge K2: Percentage of workstation with risk assessment verified in course of introduction of new machinery, materials, changing work method etc. |

| L. Emergency prepared-ness and response | L1: Percentage of workers trained on emergency procedures, including rescue activities and first aid |

| M. Procurement | M1: Percentage of periodically verified OSH requirements applied in purchase specifications M2: Percentage of purchased larger objects for which risk assessment has been carried out prior to bringing them into use |

| N. Contracting | N1: Number of contractors assessed for their compliance with OSH management requirements |

| Evaluation | |

| O. Performance monitoring and measurement | O1: Percentage of definitions of leading and lagging performance indicators subject to periodical review and update |

| P. Investigation of work-related accident, diseases and incidents and their impact on OSH | P1: Number of corrective and preventive actions carried out as a result of root cause analyzes of work-related accidents, diseases and incidents P2: Percentage of medical consultations carried out within the programme of workers’ health surveillance |

| Q. Management system audit | Q1: Percentage of OSH MS components or processes subject to assessment during internal OSH MS audits |

| R. Management review | R1: Percentage of recommendations formulated by top managers at OSH MS reviews considered in OSH improvement plans |

| Action for improvement | |

| S. Preventive and corrective action | S1: Percentage of completed corrective and preventive actions in relation to all actions initiated by OSH MS audits and reviews, OSH performance monitoring, and root cause analyses of work-related accidents, incidents and diseases S2: Percentage of completed corrective actions reviewed and evaluated for their effectiveness |

| T. Continual improvement | T1: Number of new OSH goals and objectives established in the framework of OSH MS continual improvement T2: Number of OSH management KPIs subject to benchmarking with other companies |

Podgórski, D. (2015). Measuring operational performance of OSH management system–A demonstration of AHP-based selection of leading key performance indicators. Safety science, 73, 146-166. https://www.sciencedirect.com/science/article/pii/S0925753514003063

Akroush, N. S., & El-adaway, I. H. (2017). Utilizing construction leading safety indicators: Case study of Tennessee. Journal of Management in Engineering, 33(5), 06017002. https://doi.org/10.1061/(ASCE)ME.1943-5479.0000546

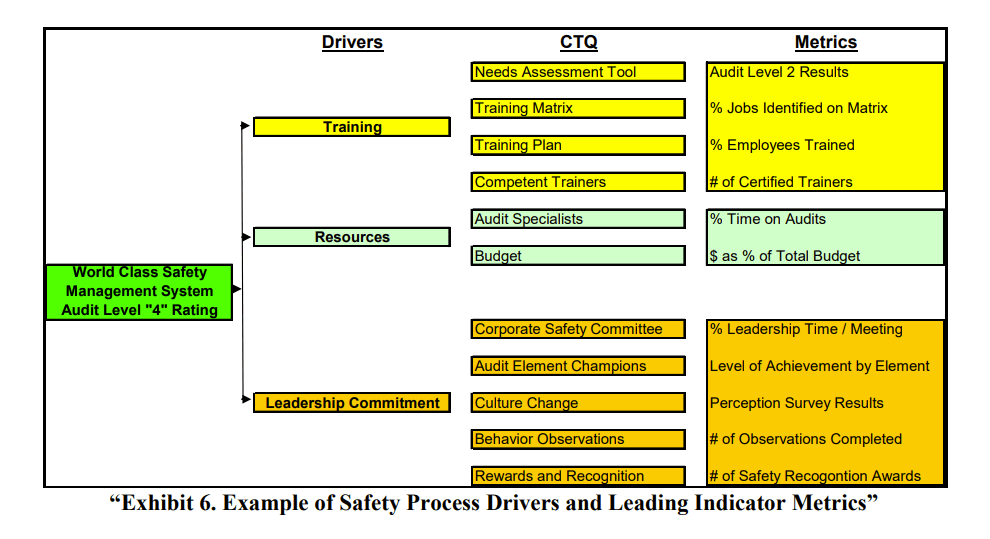

Eaton, G. H., & Little, D. E. (2009, June). Performance Metrics-Leading Indicators Deliver Sustainable Results. In ASSE Professional Development Conference and Exposition (pp. ASSE-09). ASSE. https://aeasseincludes.assp.org/proceedings/2009/docs/612.pdf

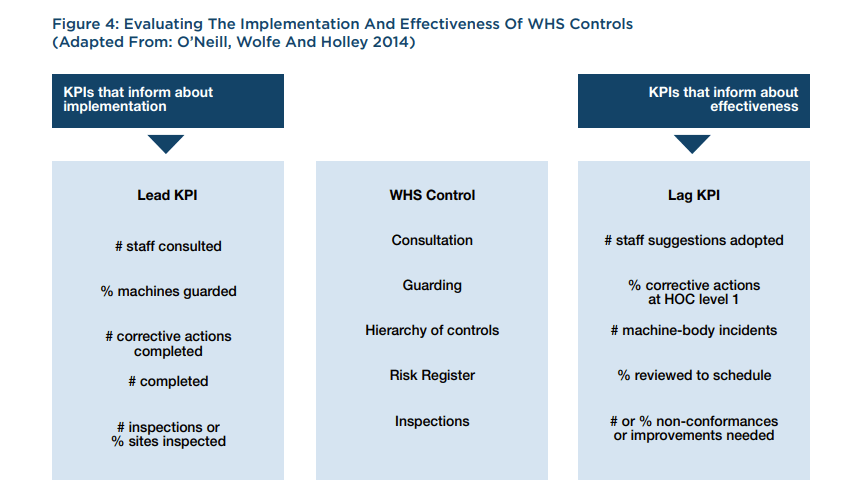

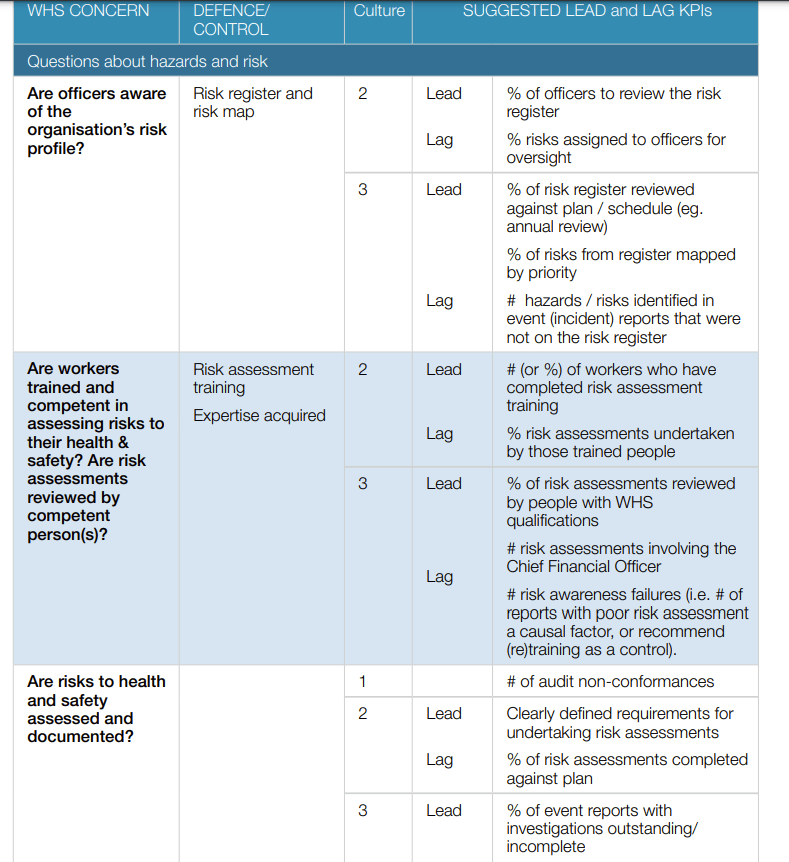

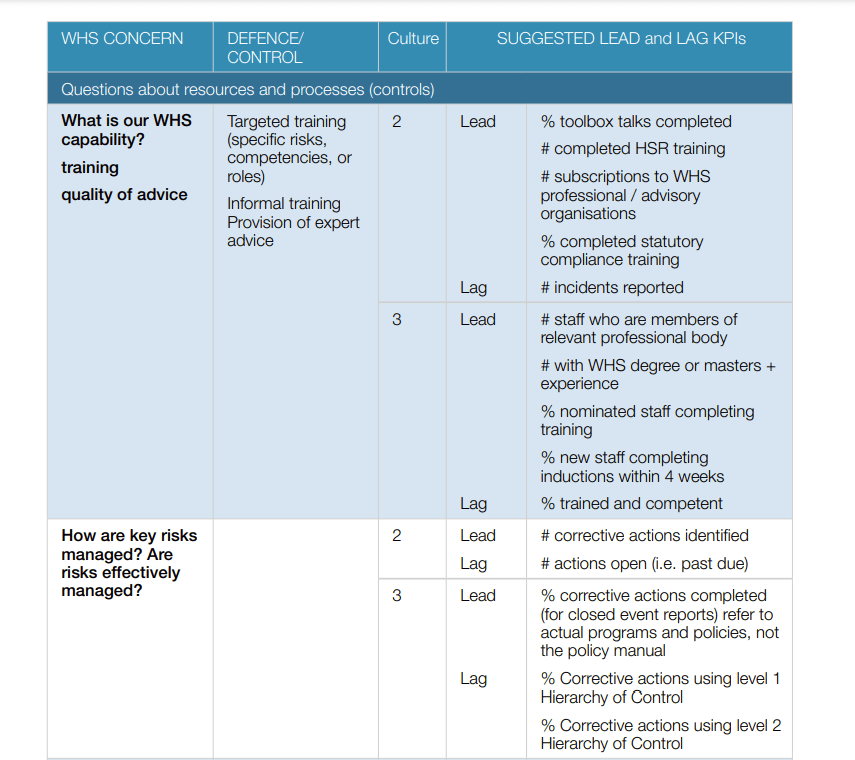

O’Neill, S & Wolfe, K, Measuring and reporting on work health & safety, Canberra, Safe Work

Australia, 2017. https://www.safeworkaustralia.gov.au/system/files/documents/1802/measuring-and-reporting-on-work-health-and-safety.pdf

Liang, H., Zhang, S., & Su, Y. (2018). Using leading and lagging indicators to select safe contractors at the prequalification stage of construction projects. International journal of occupational and environmental health, 24(1-2), 61-74. https://pmc.ncbi.nlm.nih.gov/articles/PMC6225369/

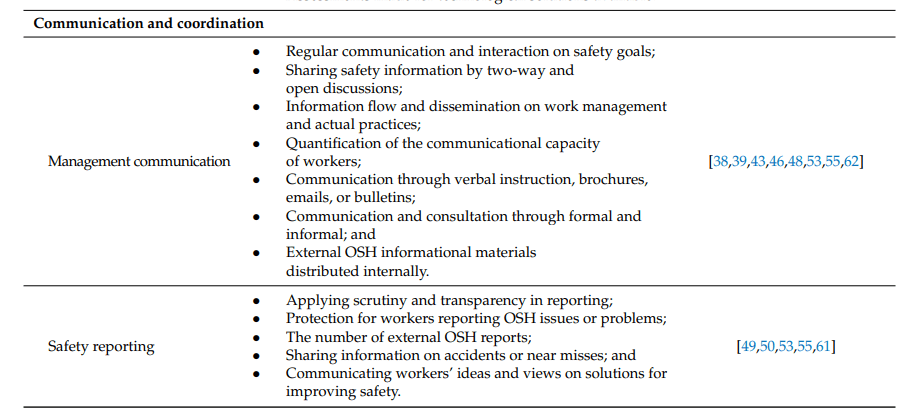

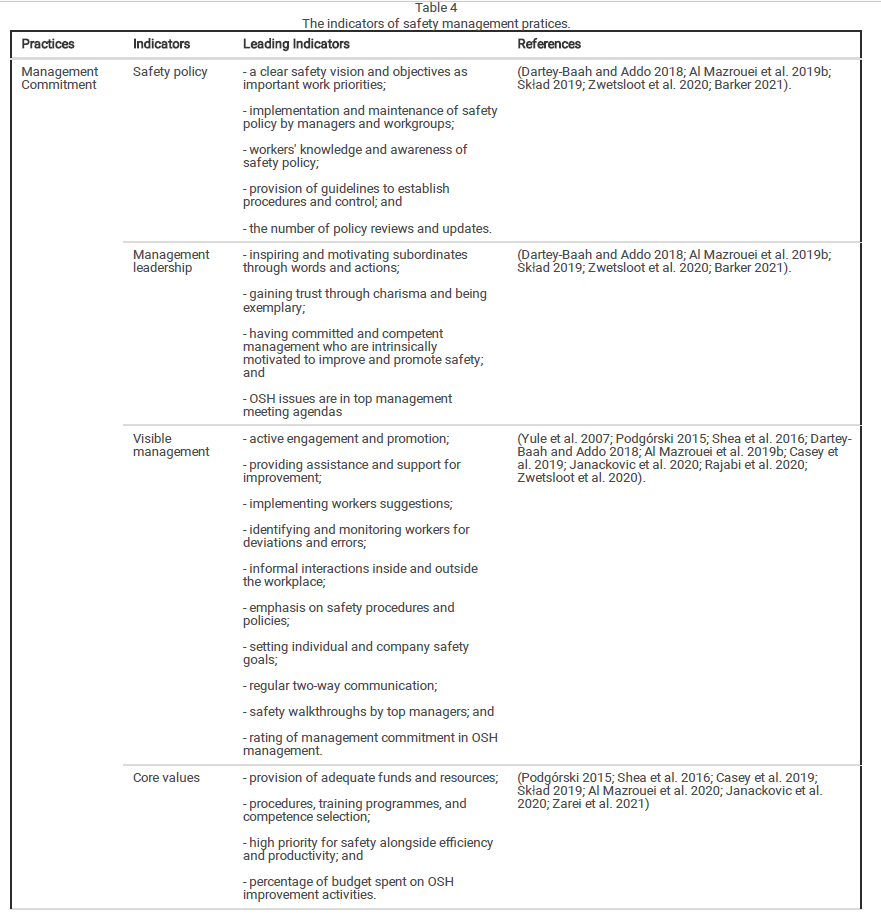

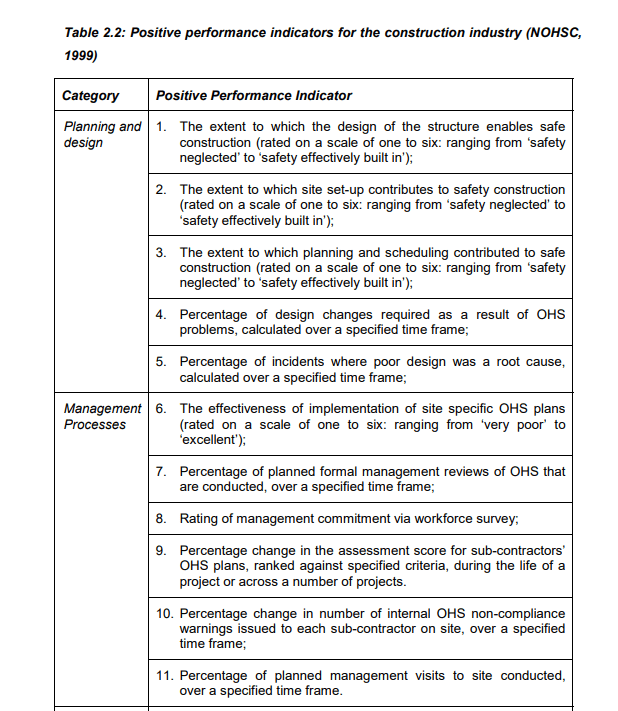

Ali, M. X. M., Arifin, K., Abas, A., Ahmad, M. A., Khairil, M., Cyio, M. B., … & Ali, M. N. (2022). Systematic literature review on indicators use in safety management practices among utility industries. International journal of environmental research and public health, 19(10), 6198. https://www.mdpi.com/1660-4601/19/10/6198/pdf

Table 1. Occupational health and safety management systems (OHSMS) areas of activity, associated criteria, and key performance indicators (KPI)

| OHSMS activity | Code | Criteria | KPIs |

|---|---|---|---|

| Policy | PO1 | A. Top management commitment | A1: The no. of OHS meetings in which top managers participate |

| PO2 | B. Communicating OHS policy & availability at workstations | B1: Percentage of employees informed about OHS policy | |

| PO3 | C. Reviewing & updating OHS policy | C1: The no. of OHS policies that have been reviewed | |

| PO4 | D. Consistency with other organizations’ policies | D1: Percentage of OHS regulations & standards applicable to workstations | |

| PO5 | E. Workers’ participation in developing OHS policy | E1: The no. of OHS hazards reported by workers | |

| PO6 | F. Simplicity & understandability of OHS policy | F1: The no. of workers who have a good understanding of OHS policy | |

| PO7 | G. Preliminary risk assessment for developing OHS policy | G1: The no. of risk assessments carried out in units | |

| PO8 | H. Supervision of OHS policy implementation | H1: The no. of managerial meetings to discuss OHS issues | |

| Planning | PL1 | I. Workers’ participation in workstation risk assessments | I1: The no. of near-miss reports by workers |

| PL2 | J. Encouraging workers to participate in risk assessments | J1: The no. of rewards given to workers for OHS hazard reports | |

| PL3 | K. Recording & reporting OHS activities for risk assessment planning | K1: The no. of units in which OHS report & record-keeping systems exist | |

| PL4 | L. Communicating OHS activities | L1: The no. of OHS brochures distributed to workers | |

| PL5 | M. Reviewing & updating risk assessment policies | M1: The no. of risk assessments updated | |

| PL6 | N. Using units’ OHS data during OHS program development | N1: The no. of near misses | |

| PL7 | O. Deadline for OHS programs | O1: The no. of OHS programs carried out in a defined period | |

| PL8 | P. Announcing OHS programs & objectives | P1: The no. of OHS events for employees | |

| PL9 | Q. Allocating financial resources to OHS programs | Q1: Financial resources allocated for OHS/y ($) | |

| Implementation and operation | IM1 | R. Training workers in OHS to ensure competence | R1: The no. of h allocated for OHS training per person |

| IM2 | S. Using risk assessment results during OHS training plan development | S1: The no. of workstations for which a risk assessment exists & corrective action or changes have been made | |

| IM3 | T. Announcing OHS activities & issues to workers | T1: The no. of OHS posters, bulletins, or newsletters published | |

| IM4 | U. Workers’ participation in OHS activities | U1: The no. of accidents due to a lack of PPE | |

| IM5 | V. Incentive for workers to participate in OHS activities | V1: The no. of rewards for participating in OHS activities | |

| IM6 | W. OHS documentation & regulation | W1: The no. of tasks that have OHS procedures | |

| IM7 | X. Allocating financial resources to ERP | X1: The no. of ERP training course completed | |

| IM8 | Y. Emergency response drills based on risk assessment results | Y1: The no. of workstations that have an ERP procedure | |

| IM9 | Z. Practical emergency response drills based on procedures | Z1: The no. of emergency response drills performed | |

| IM10 | AA. Provision of emergency response equipment & regular inspection & testing | AA1: The no. of verified OHS procedures applied during purchase or use | |

| IM11 | AB. Establishing an organizational structure for OHS | AB1: The no. of units that have an OHS reporting system | |

| Checking | CH1 | AC. Measuring & monitoring based on risk assessment | AC1: The no. of units where OHS performance has been evaluated |

| CH2 | AD. Measuring & monitoring based on lagging indicators | AD1: The no. of OHS violations, & no. of sanctions | |

| CH3 | AE. Record & control systems for OHS activities | AE1: The no. of units that have OHS reporting systems | |

| CH4 | AF. Announcing results of OHS audits to workers | AF1: The no. of meetings held with workers on OHS issues | |

| CH5 | AG. Deadline for OHS audits | AG1: The no. of audits performed in a given period | |

| CH6 | AH. Continuous review of OHS audits | AH1: The no. of audits that have been reviewed | |

| CH7 | AI. Worker involvement in accident investigations | AI1: The no. of accident investigations carried out with worker participation | |

| CH8 | AJ. Reviewing & updating accident investigations | AJ1: The no. of training courses on accident investigation | |

| CH9 | AK. Announcing accident investigation results to employees | AK1: The no. of accident reports sent to units | |

| CH10 | AL. Announcing corrective & preventive actions | AL1: The no. of meetings carried out to discuss corrective & preventive actions | |

| CH11 | AM. Presence of a recording, reporting & analysis system for accidents | AM1: The no. of accidents, reported near misses | |

| Management review | MA1 | AN. Having a timeframe to review meetings | AN1: The no. of review meetings carried out |

| MA2 | AO. Results of OHS activities available for review | AO1: The no. of OHS performance reports from units | |

| MA3 | AP. OHS indicators included in reviews | AP1: The no. of recommendations for continual improvement | |

| MA4 | AQ. Presence of a manager during review meetings | AQ1: The no. of managers of units attending review meetings |

Mohammadfam, I., Kamalinia, M., Momeni, M., Golmohammadi, R., Hamidi, Y., & Soltanian, A. (2017). Evaluation of the quality of occupational health and safety management systems based on key performance indicators in certified organizations. Safety and health at work, 8(2), 156-161. https://www.sciencedirect.com/science/article/pii/S2093791116300634

Johnsen, S. O., Okstad, E., Aas, A. L., & Skramstad, T. (2012). Proactive indicators to control risks in operations of oil and gas fields. SPE Economics & Management, 4(02), 90-105. https://oshwiki.osha.europa.eu/sites/oshwiki/files/2022-03/v17i2art2_Johnsen.pdf

Brown, M. (2009, September). Developing KPIs that drive process safety improvement. In Hazards SSI, Symposium series (No. 155). https://www.icheme.org/media/9659/xxi-paper-031.pdf

Walaski, P. (2020). The role of leading & lagging indicators in OSH performance management. Professional Safety, 65(08), 29-35. https://aeasseincludes.assp.org/professionalsafety/pastissues/065/08/F2Walaski_0820.pdf

Caldarescu, G., Florea, L., Nagit, G., & Bernevig, M. A. (2021). The importance of performance indicators in occupational safety and health management-a review. In MATEC Web of Conferences (Vol. 343, p. 10016). EDP Sciences. https://www.matec-conferences.org/articles/matecconf/pdf/2021/12/matecconf_mse21_10016.pdf

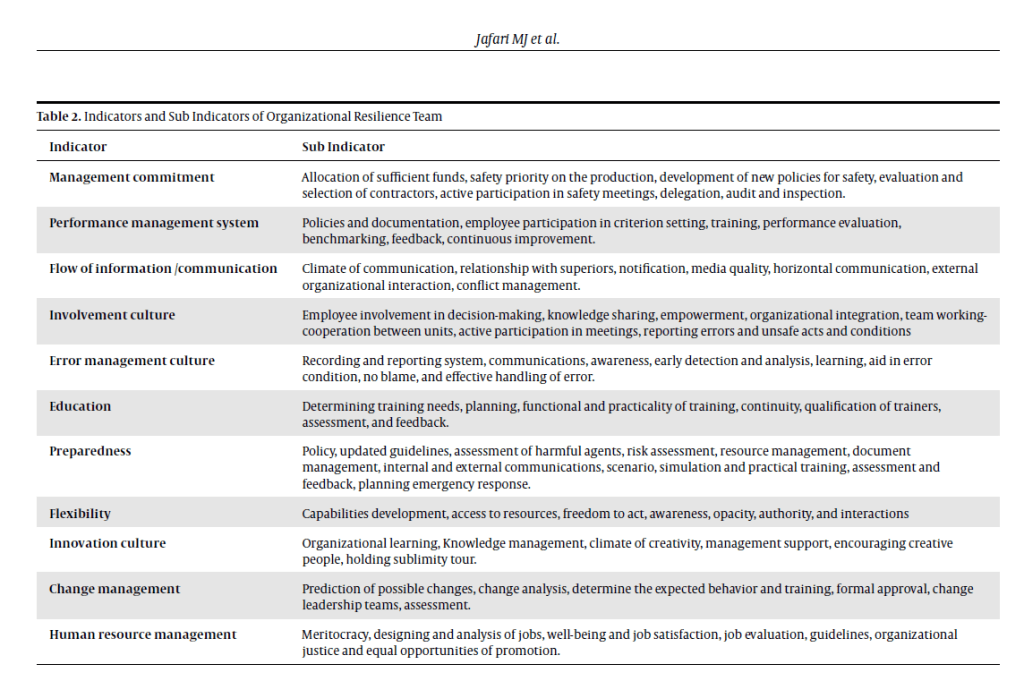

Jafari, M. J., Nodoushan, R. J., Shirali, G. A., Khodakarim, S., & Zare, H. K. (2018). Indicators of organizational resilience in critical sociotechnical systems: A qualitative study for the refinery complex. Health Scope, 7(3). https://brieflands.com/articles/healthscope-14134.pdf

Ali, M. X. M., Arifin, K., Abas, A., Ahmad, M. A., Khairil, M., Cyio, M. B., … & Ali, M. N. (2022). Systematic literature review on indicators use in safety management practices among utility industries. International journal of environmental research and public health, 19(10), 6198. https://www.mdpi.com/1660-4601/19/10/6198/pdf

Janackovic, G. L., Savic, S. M., & Stankovic, M. S. (2013). Selection and ranking of occupational safety indicators based on fuzzy AHP: A case study in road construction companies: Case study. South African Journal of Industrial Engineering, 24(3), 175-189. https://www.scielo.org.za/pdf/sajie/v24n3/15.pdf

Safety, A., & Council, C. (2005). Guidance on the Use of Positive Performance Indicators to Improve Workplace Health and Safety. Safe Work Australia, Commonwealth of Australia: Canberra, Australia. https://www.safeworkaustralia.gov.au/system/files/documents/1702/guidanceonuseofppis_2005_pdf.pdf

Simpson, I. R. (2006). An investigation into the use of positive performance indicators to measure OHS performance (Doctoral dissertation, UNSW Sydney). https://scholar.archive.org/work/g3zd4vfabnh6vmxjaj2tntm7ga/access/wayback/https://unsworks.unsw.edu.au/server/api/core/bitstreams/576cdde4-d975-4baf-b0c6-3d4fa32c5268/content

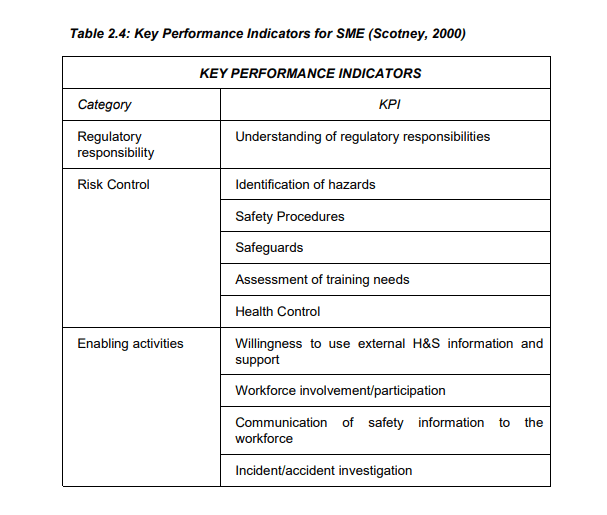

Agumba, J. N., Pretorius, J. H., & Haupt, T. C. (2014). Important health and safety performance improvement indicators for small & medium construction enterprises in South Africa: eliciting expert opinion using the Delphi Technique. Ergonomics SA: Journal of the Ergonomics Society of South Africa, 26(2), 3-22. https://www.researchgate.net/profile/Theo-Haupt/publication/327690913_Important_Health_and_Safety_Performance_Improvement_Indicators_for_Small_Medium_Construction_Enterprises_in_South_Africa_Eliciting_Expert_Opinion_Using_the_Delphi_Technique/links/5b9f809245851574f7d1c8f5/Important-Health-and-Safety-Performance-Improvement-Indicators-for-Small-Medium-Construction-Enterprises-in-South-Africa-Eliciting-Expert-Opinion-Using-the-Delphi-Technique.pdf

Psychosocial Indicators

Bergh, L. I. V., Hinna, S., Leka, S., & Jain, A. (2014). Developing a performance indicator for psychosocial risk in the oil and gas industry. Safety science, 62, 98-106. https://www.sciencedirect.com/science/article/pii/S0925753513001835?casa_token=ss3wP2KqnnQAAAAA:XWT155TZ3S96f4OOK3IHHjxgfXCDecYmVsZvX9UrH0sdWddtsr8YKhO4HjaP7qMVujgUXgSLxaJB

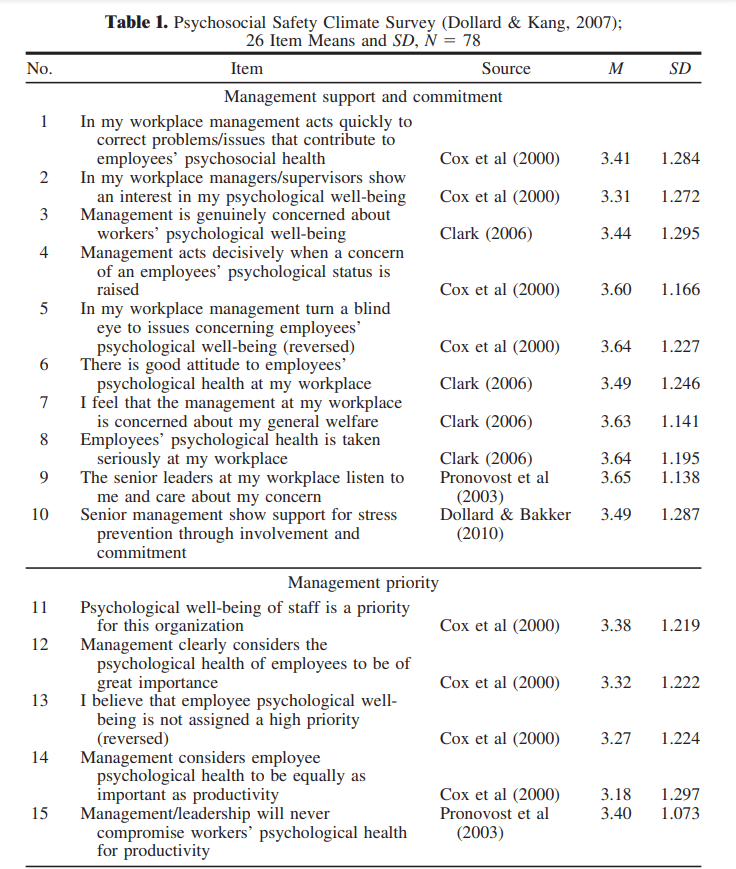

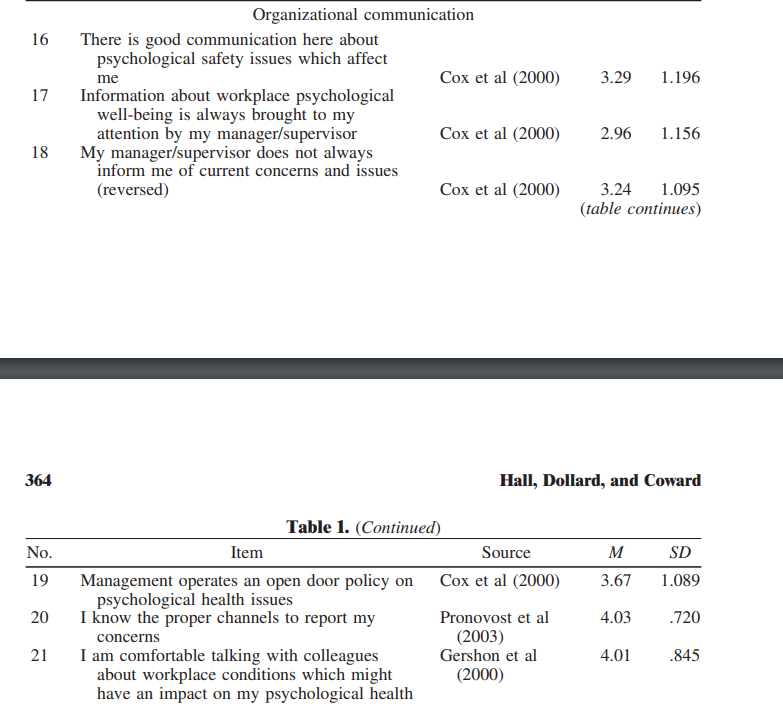

Hall, G. B., Dollard, M. F., & Coward, J. (2010). Psychosocial safety climate: Development of the PSC-12. International journal of stress management, 17(4), 353. https://d1wqtxts1xzle7.cloudfront.net/108839351/a002132020231212-1-vio1ds-libre.pdf?1702401327=&response-content-disposition=inline%3B+filename%3DPsychosocial_safety_climate_Development.pdf&Expires=1731894404&Signature=fa~VWgdrep27jPz~oKc9Uns61Y6mkwtiSdqlJthvhoogrx1Rl79ogWePf1FUlh3A-7AgC5DUUF1Oj0UnaANV7YoNfvToAbGBtY8X-uNPit9ifJoaZS3l~7mZyPWTXkQmo1IYmXxcC-zYfr31uY~EHXcSgJZdkQcodCEPYJO2zYyQfRpWsheYkpOKdgbW9EeYJF2mHxVUDqt4VmPQx~3LTFrJNXWg5S~~JuXtpt4PWRI7WkTJlr3uBt6HZFQrteHUgTV901isvi3VGwcaY4gFAMHCj-0CQgQDb~jnRHTm9Ii5DOpUM1o27xa4NYLbuZiRSBFN4vtGgmH2QEKdqexb1Q__&Key-Pair-Id=APKAJLOHF5GGSLRBV4ZA

Berthelsen, H., Muhonen, T., Bergström, G., Westerlund, H., & Dollard, M. F. (2020). Benchmarks for evidence-based risk assessment with the Swedish version of the 4-item psychosocial safety climate scale. International Journal of Environmental Research and Public Health, 17(22), 8675. https://www.mdpi.com/1660-4601/17/22/8675/pdf

Weaver, B., Kirk-Brown, A., Goodwin, D., & Oxley, J. (2023). Psychosocial safety behavior: A scoping review of behavior-based approaches to workplace psychosocial safety. Journal of safety research, 84, 33-40. https://doi.org/10.1016/j.jsr.2022.10.006

Caveats, Limitations, Advice on Indicators

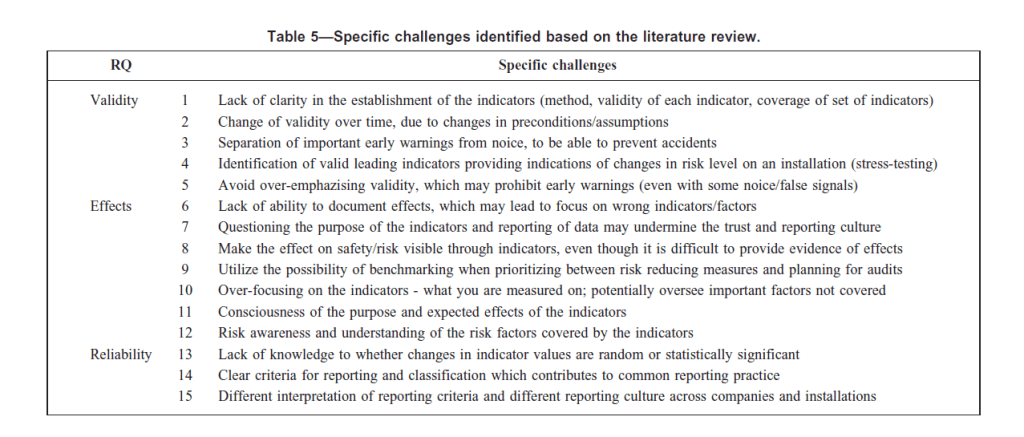

Kilskar, S. S., Øien, K., Tinmannsvik, R. K., Heggland, J. E., Hinderaker, R. H., & Wiig, S. (2016, April). Major Accident Indicators in High Risk Industries-A Literature Review. In SPE International Conference and Exhibition on Health, Safety, Environment, and Sustainability? (p. D021S031R001). SPE.

Øien, K., Utne, I. B., Tinmannsvik, R. K., & Massaiu, S. (2011). Building safety indicators: Part 2–application, practices and results. Safety science, 49(2), 162-171.

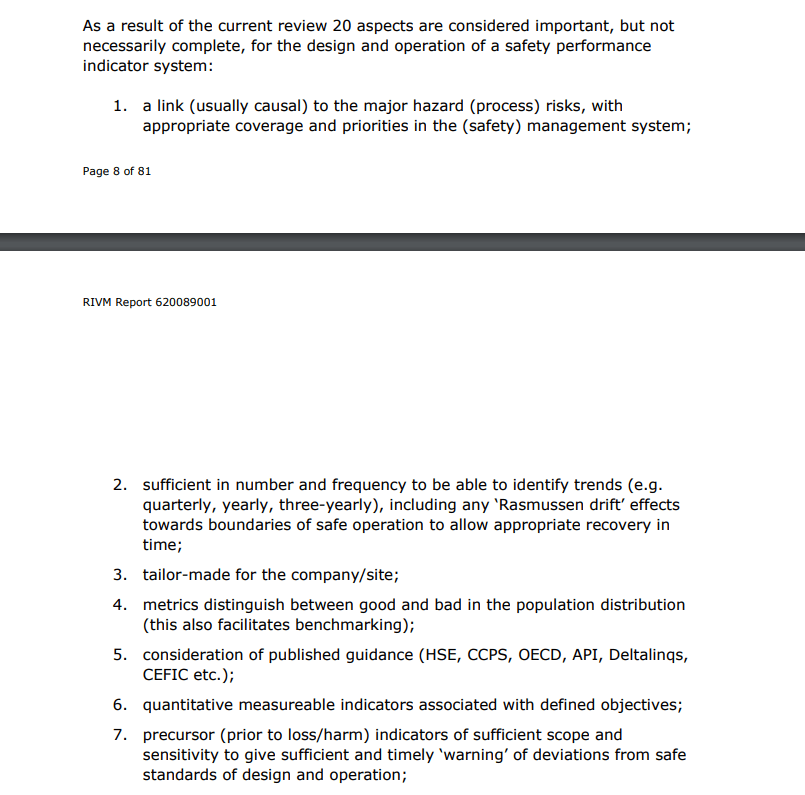

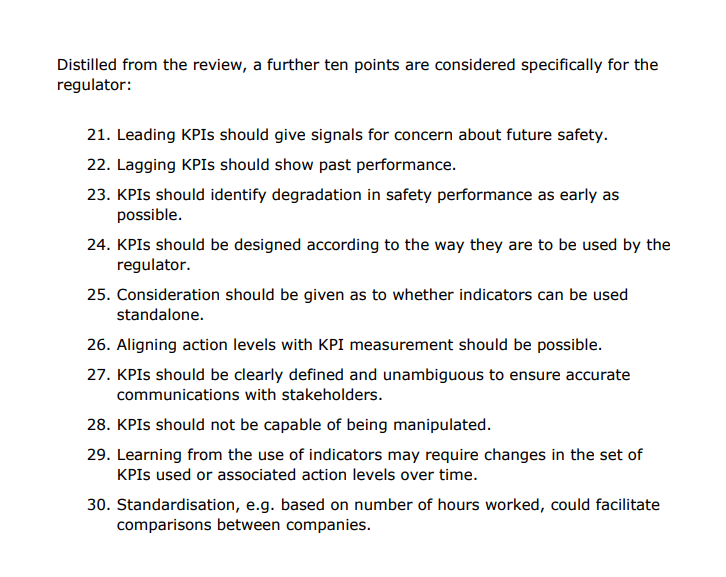

Bellamy, L. J., & Sol, V. M. (2012). A literature review on safety performance indicators supporting the control of major hazards. https://rivm.openrepository.com/bitstream/handle/10029/256345/620089001.pdf?sequence=3&isAllowed=y

Table 2. Challenges and considerations associated with stages of development, implementation and adoption (use)of leading indicators.

| Stages | Challenges and precautions | Considerations and potential solutions |

|---|---|---|

| Development of leading indicators | Lacking consensus on the definition, purpose and type of LIs and the indicated phenomena (i.e. safety), and absence of clear guidance or tool on how to develop LIs (Guo and Yiu, 2015; Akroush and El-adaway, 2018; Haji et al., 2022). | Successful utilisation of LIs requires three solutions viz.: 1) a clear conceptual framework for deriving LIs and their associated set of purposes; 2) a selection process that determines which LIs are to be applied and how; 3) a specification of how LIs fit into management and decision-making processes (Guo and Yiu, 2015). |

| Avoiding fragmented or single level view on LIs and their effect on safety performance (Xu et al., 2021). | LIs should be developed to describe and monitor specific safety conditions through a systematic development process where safety conditions are viewed as a dynamic phenomenon created, improved, and maintained by safety practices (Guo and Yiu, 2015). | |

| Removing or significantly reducing biases in the process of developing, selecting, using and measuring LIs (Leveson, 2015). | While heuristic biases cannot be eliminated, a structured method for identifying, detecting, and managing LIs can reduce the impact of our biases (Leveson, 2015). | |

| Tending to use only statistically sensible data by safety managers hinders recognition, identification or effective use of LIs (Hopkins, 2009, Haji et al., 2022). | While a quantitative indicator can be useful for benchmarking, a qualitative indicator provides deeper explanation of the how or why and opens opportunity for improvement by providing insightful context (Mengolini and Debarberis, 2008, Oswald, 2020). | |

| There is no specific set of LIs to monitor safety and safety culture (Mengolini and Debarberis, 2008). | LIs should be developed for: product/element level, system level and system of systems level because every level requires a different set of LIs (Rhodes et al., 2009). | |

| Avoiding adoption and use of LIs by directly sourcing from other projects, organisations or industries without adjustments (Xu et al., 2021). | Since safety management within each organisation is unique and contextual, organisation or project specific LIs must be considered (Xu et al., 2021). | |

| The difficulty in developing any theoretically well-motivated indicators that can be ‘objectively’ linked and shown to predict actual major process incidents prevents the generation of effective and believable LIs (Hudson, 2009). | Initially, conditions impacting safety changes must be studied. After which LIs should be developed based on the assumptions generated (i.e. how safety is changing) (Leveson, 2015). | |

| Implementation of leading indicators | Difficulty to convey to users in worksites the constructs of LIs (Costin et al., 2019). | To develop established, learnt and shared understanding of: what is normal, expected and desired (versus what is not normal, unexpected and undesirable); what to observe, monitor, expect and fear when experiencing LIs in worksites (Costin et al., 2019). |

| Due to similarity to classical metrics in the base measures collected, it may be difficult to secure a buy-in from an organisation’s management and practitioners to use LIs as they may be superficially dismissed as “something we are already doing.” (Rhodes et al., 2009; Akroush and El-adaway, 2018). | Project leadership teams should: 1) self-determine (with input from their safety professionals and workers) the LIs needed to drive higher levels of performance; and 2) be willing to hold themselves (and their respective teams) accountable for sustained performance improvement (Toellner, 2014). | |

| Effective ways to present the information in a concise and graphical form are required to address the specific information needs of the organisation or project to augment effective decisions (Rhodes et al., 2009, Toellner, 2014). | Data must be presented in an unambiguous fashion (Toellner, 2014). | |

| A dearth of information about LIs’ validation hinders their extrapolation (Rhodes et al., 2009). | In the early phases of LI use, the individual organisation still should further validate the conditions under which a LI can be most useful in their organisation by observing its usefulness in various programmes over time (Rhodes et al., 2009). | |

| The fact that interpretation of LIs is a blend of statistical analysis and subjective assessment based on experience (Rhodes et al., 2009). | Guidance to tailor LIs to the project environment and usage experience must be carefully developed with highly knowledgeable staff or subject matter experts (Rhodes et al., 2009). | |

| It may be difficult to secure leadership support for using high level engineering talent for a “task” (for interpreting the collected data, i.e. LIs) that was previously performed by junior analysts (Rhodes et al., 2009). | The effective use of LIs requires: a systems engineering programme in order to gather and analyse the indicators; dedicatation of experienced personnel’s time to the interpretation of the resulting information. Utilising indicators for real-time management of programmes requires decision making using this information at all levels (Rhodes et al., 2009). | |

| Deciding whether to use LIs as standalone, combined or aggregated sets could become challenging (Rhodes et al., 2009). | Selecting appropriate LIs in the context of organisational factors is a rich area for future research. Future studies must focus on: understanding the relationships between the LIs; whether it is possible or necessary to find appropriate ways to aggregate LIs; and when aggregation should not be undertaken (Rhodes et al., 2009). | |

| Adequate training must be developed for these indicators to obtain a wide level of infusion across industry. This includes two levels of training, one for the decision-makers and one for the measurement practitioners (Rhodes et al., 2009). | Decision-makers should receive a short course focused on describing LIs, the utility of the indicators, and the resources needed to implement them. Practitioners training courses should focus on selecting the optimum indicators, how to analyse and interpret for leading insight rather than lagging insight, and detail discussion and exercise for the indicator (Rhodes et al., 2009). | |

| Adoption (use) of leading indicators | A critical aspect of adopting LIs is their potential manipulation when corporate safety culture is not firmly established. The focus on “what can be measured” rather than “what should be measured” might have a misleading impact on understanding and management of systems’ states (Hudson, 2009, Patriarca et al., 2019). | To adopt a dynamic and agile methodology which allows to continuously identify and refine the most appropriate LIs (Patriarca et al., 2019). |

| Difficulty in determining an accurate forecast of accidents due to the complexity and abundance of variables in safety systems constitute an obstacle in LIs use (Mengolini and Debarberis, 2008, Guo and Yiu, 2015, Akroush and El-adaway, 2017). | During the implementation process, LIs should be continually improved and adjusted by comparing the results with the intended effects (Akroush and El-adaway, 2017). | |

| Data collection takes time and the lack of a centralised repository to build a core history overshadows potential benefits of using LIs (Rhodes et al., 2009, Guo and Yiu, 2015). | Collecting LIs and other contextual data in a centralised database enables establishment of safety analytics where organisations can identify holes in their safety systems and provide a source of positive safety metrics for employees (Pettinger, 2013). |

Bayramova, A., Edwards, D. J., Roberts, C., & Rillie, I. (2024). Unravelling the Gordian knot of leading indicators. Safety Science, 177, 106603. https://www.sciencedirect.com/science/article/pii/S0925753524001930

Relationship with Performance and Other Measures

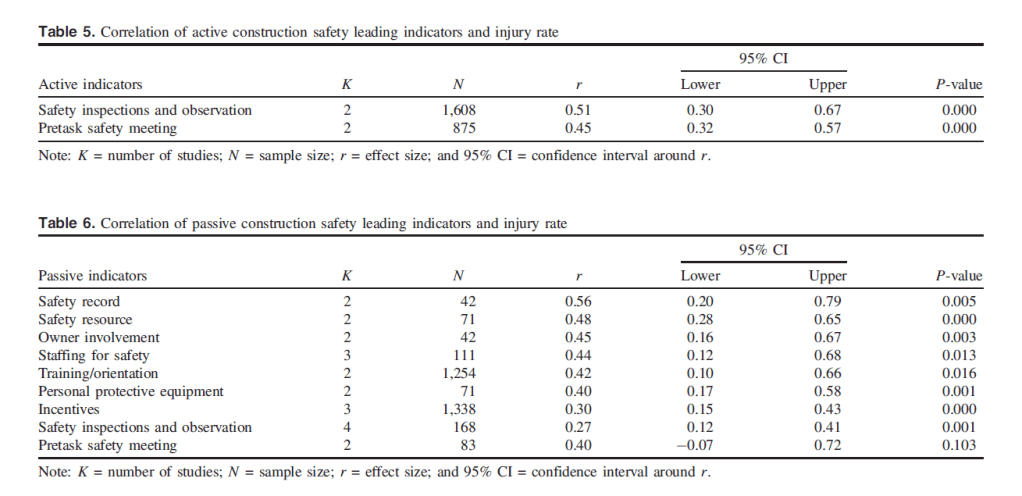

Alruqi, W. M., & Hallowell, M. R. (2019). Critical success factors for construction safety: Review and meta-analysis of safety leading indicators. Journal of construction engineering and management, 145(3), 04019005.

Caldarescu, G., Florea, L., Nagit, G., & Bernevig, M. A. (2021). The importance of performance indicators in occupational safety and health management-a review. In MATEC Web of Conferences (Vol. 343, p. 10016). EDP Sciences. https://www.matec-conferences.org/articles/matecconf/pdf/2021/12/matecconf_mse21_10016.pdf

4 thoughts on “Research Compendium: Safety & Risk Performance indicators (lead, lag, drive, process safety + more)”