Another from Deming while I’m on the theme.

Not much needs to be said – I think it does a lot of talking itself.

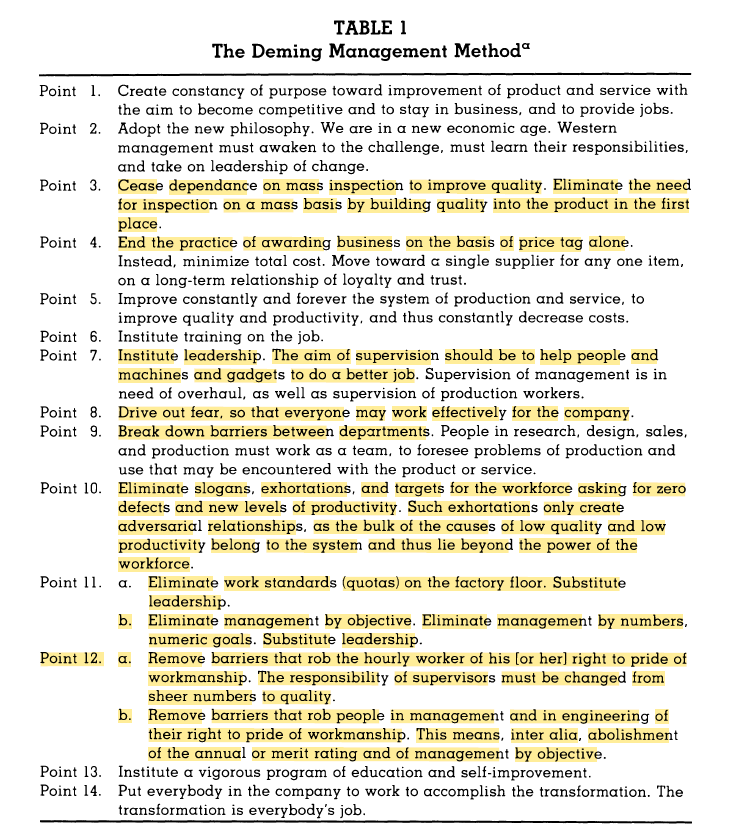

Deming promoted:

· Ceasing the dependence of trying to inspect-in quality

· Aim for continuous learning, testing and improvement (e.g. plan, do, STUDY, act)

· He was critical of zero defect approaches, arguing them to be insufficient

· “Drive out fear, so that everyone may work effectively for the company”

· On fear, he said in the New Economics that “Fear invites wrong figures. Bearers of bad news fare badly. To keep his job, anyone may present to his boss only good news”

· “Eliminate slogans, exhortations, and targets for the workforce asking for zero defects and new levels of productivity. Such exhortations only create adversarial relationships, as the bulk of the causes of low quality and low productivity belong to the system and thus lie beyond the power of the workforce”

· Remove barriers that “rob the hourly worker of his [or her] right to pride of workmanship”

· “Remove barriers that rob people in management and in engineering of their right to pride of workmanship”

Refs:

1) A Theory of Quality Management Underlying the Deming Management Method Author(s): John C. Anderson, Manus Rungtusanatham and Roger G. Schroeder Source: The Academy of Management Review, Vol. 19, No. 3, Special Issue: “Total Quality” (Jul., 1994), pp. 472-509

2) The New Economics, 2nd Ed. WE Deming