Really interesting 2004 paper discussing how to study the failures associated with organisational artefacts.

Artefacts are “rules, procedures, instructions, authority structures and so on that are designed, like physical devices, but have organizational rather than physical functions”.

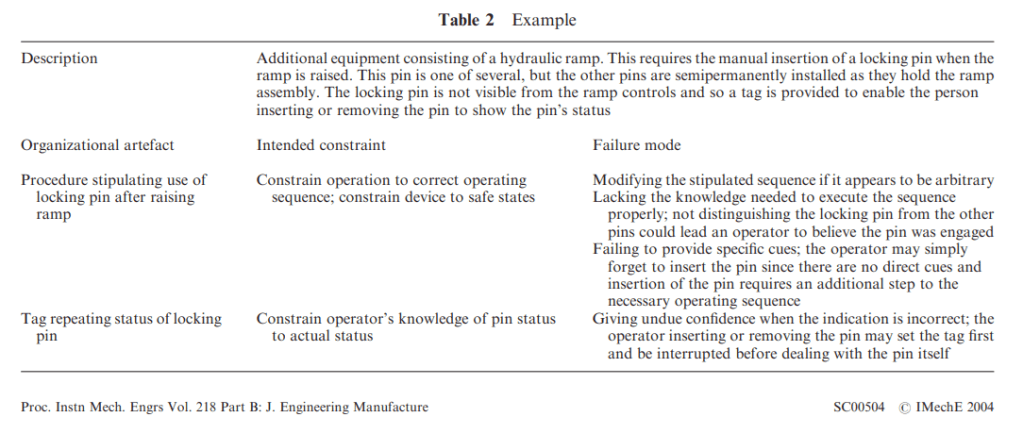

It’s argued that studying failures of artefacts, like in FMEA, isn’t the same as physical failure modes, and hence requires a different approach.

Extracts:

· “Designed systems inevitably rely to some degree for their protection on organizational artefacts”

· Org artefacts are “typically used to protect systems when it is not feasible or cost effective to use technical measures”, like “operating procedures, codes of practice, rules of engagement and authority structures that define who has responsibility in particular situations”

· “Since they are often as important as technical devices in maintaining safety, they need to be analysed in parallel with the technical devices whenever a designer is conducting a risk assessment or failure analysis”

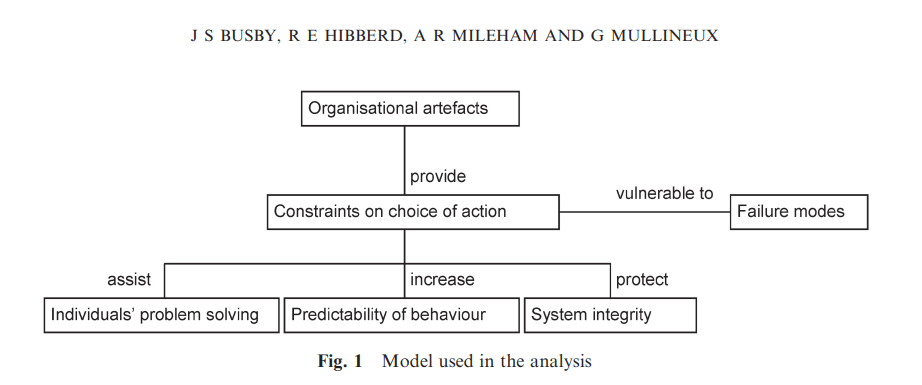

· They suggest that studying the effects of artefacts as constraints on human action, like “traffic rules constrain manoeuvres to be of particular kinds, operating instructions constrain operations to take place in a particular sequence and so on”

· “These constraints help the people in the system by narrowing down the choices that they have to make, by making people’s actions more predictable to other people in the system and by protecting the integrity of the system by constraining activity to just that of non-hazardous kinds”

· Whereas breaking physical systems into constituent components is relatively straightforward, artefacts aren’t so simple

· The constraints that artefacts provide “are easily undermined when they do not make sense, when they obstruct people in normal tasks and when they are essentially afterthoughts in the design process”, hence their effects aren’t as straightforward as physical components

· “It seems clear from the analysis of historical failures, that organizational elements, and organizational artefacts in particular, contribute to risk and yet are almost universally relied on to some extent to protect designed systems from failure. This means that any technical risk analysis needs to be accompanied by an organizational [artefact] risk analysis”

· “Applying a technique such as FMEA directly, however, does not work well because organizational artefacts do not fail in an analogous way to physical devices. A more appropriate form of analysis is to identify the constraints that these organizational artefacts provide, and then to identify ways in which the constraints can become ineffective during the operation of the system”

Ref: Busby, J. S., Hibberd, R. E., Mileham, A. R., & Mullineux, G. (2004). Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 218(9), 1211-1215.

Study link: https://www.generalpurposehosting.com/papers/14492433n.pdf