Means to observe, assess and validate barrier availability are numerous. You find them everywhere, in different domains and informed by different frameworks (e.g. via bow tie approaches, energy models, ICMM’s CCM, barrier approaches in oil & gas and more).

Here’s one of many. This study tested an approach in construction.

Not going into detail about the barrier index measure, just a few extracts:

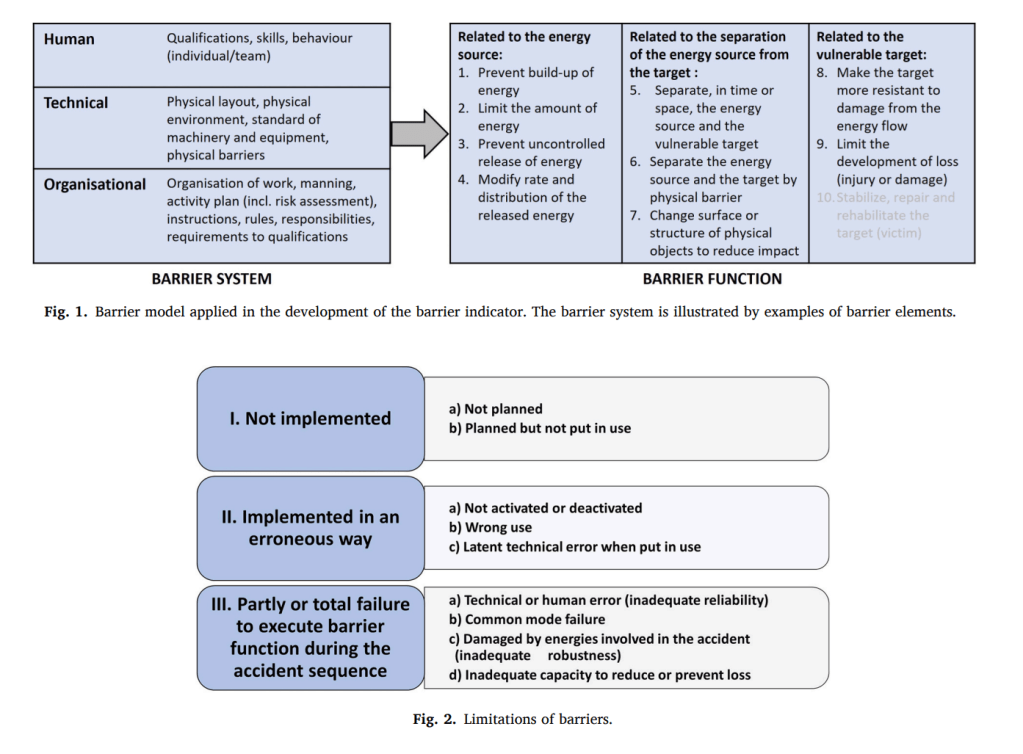

· Classical barrier approaches are rooted in energy models, and interestingly they note that in construction work, “the energy flow may be the same as that under controlled conditions is essential for the execution of work”

· Image 1 highlights the barrier model underpinning their barrier inspection & index measures

· 9 of Haddon’s 10 countermeasures were incorporated into the barrier functions

· Barrier functions (things that the barriers do) are achieved by a barrier system, and the barrier system is made up of elements

· In this conceptualisation, barriers are either passive or active, where “Passive barriers only include technical elements and are independent of any operational control system to execute the barrier function. A guardrail is an example of a passive barrier. An active barrier, on the other hand, is more complex and may consist of several human, technical, and organizational barrier elements”

· The barrier indicator is a “real-time indicator based on audits of construction activities at individual sites”, which is like the TR observation method (see my site as I’ve covered this before)

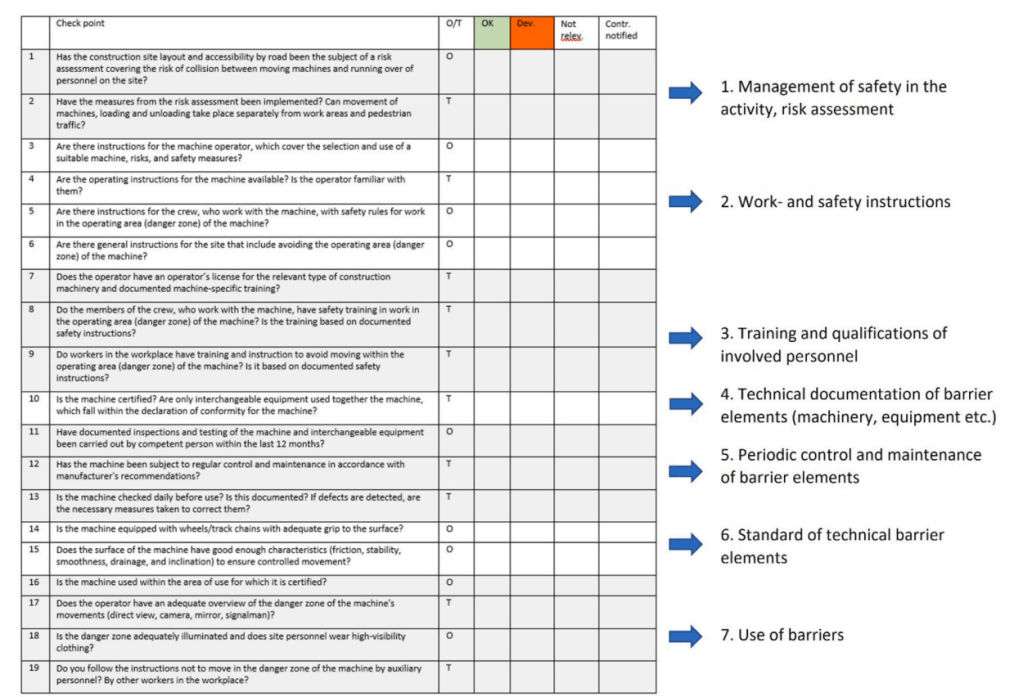

· Image 2 is an example barrier evaluation checklist, with different barrier functions and elements under review

· Per the checklist – topic 1 targets indirect checks of whether adequate measures have been taken in the planning and risk assessment of construction work, topics 2 and 3 cover measures of qualifications and skills, topics 4 and 5 address measures at ensuring adequate standard of machinery and equipment, and topic 7 captures observable human performance

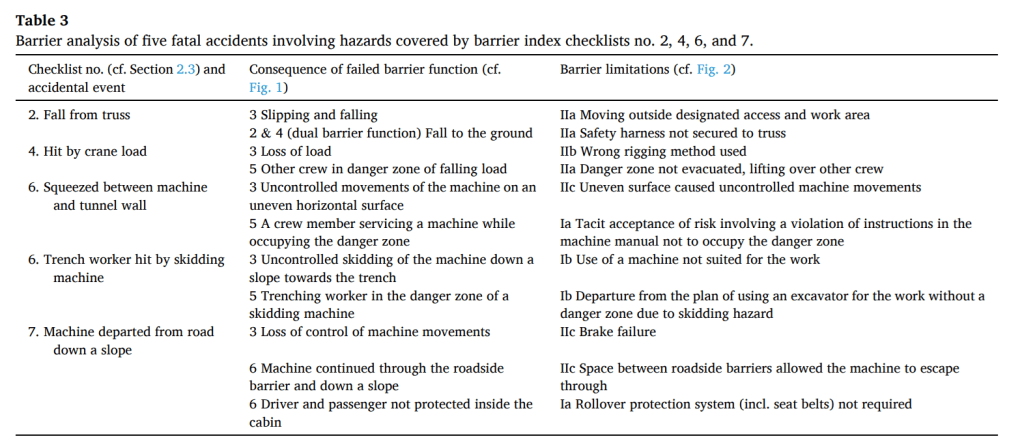

· Image 3 shows an output of several barrier checklists – which covers how the barrier didn’t function or used as expected

· Based on assessments within this study, 144 checklist items were checked and of these, 100 checks showed satisfactory results, and “44 checks were classified as deviations” – resulting in a barrier index of 69%

· “four deviations not related to inadequate documentation were based on observable physical conditions and results of interviews and included missing fall-arrest system, missing cordoning off, and disrespect for the danger zone of machines”

· They argue that field tests demonstrated the usefulness of the barrier indicator for both checking individual barriers in real-time & overall assessments of barrier systems

Ref: Kjellén, U. (2023). Preventing fatal accidents in construction through the management of barriers. Heliyon, 9(11).

Shout me a coffee (one-off or monthly recurring)

Study link: https://doi.org/10.1016/j.heliyon.2023.e21715