This article discussed learning from normal work, via semi-structured episodic interviews.

It’s open access, so not a summary.

Extracts:

· Briefly discussing historical safety progression, “safety progress was achieved by expanding existing rules to cover more potential failures, and safety failures resulted from gaps in rules or their lack of application”

· “However, no procedure, no matter how exhaustive the attempt to write it completely, will cover the variability of real situations”

· “Therefore, it will not be possible to promote complete safety, and gaps will continue to exist”

· Many proximal causes can be “expected to be symptoms of problems at the organizational or system level”

· “Similarly, “human error” should be seen as a consequence of systemic factors”

· “Behaviors are not problems, but rather expressions of problems”

· “Normal work is defined by the way in which the individual adapts and overcomes the various challenges they may encounter during their daily activities, so that operations are completed successfully and without incidents”

· “Most of the time, operations are completed successfully, and it is assumed that the system worked as designed and people worked as imagined”, and when something goes wrong, it’s natural to assume that “something special … did not work”

· “However, when unwanted or desired events occur in complex systems, people are usually doing the same kind of things they normally do — normal work”

· “What differs is the set of circumstances, interactions, and patterns of normal and necessary performance variability that allow things to work most of the time”

· “Human performance is not limited to the prescription of rules and regulations, but rather to what occurs due to solutions to get the work done”

· “The adaptability of human work is the reason for its efficiency and, at the same time, it is the reason for the errors that occur, although it is never the cause of error”

· “With interviews it is possible to obtain valuable information about leverage points, which are, “places within a complex system (a corporation, an economy, a living body, a city, an ecosystem) where a small change in something can produce large changes in everything”

· “Qualified people intuitively know where the leverage points are located in their work”

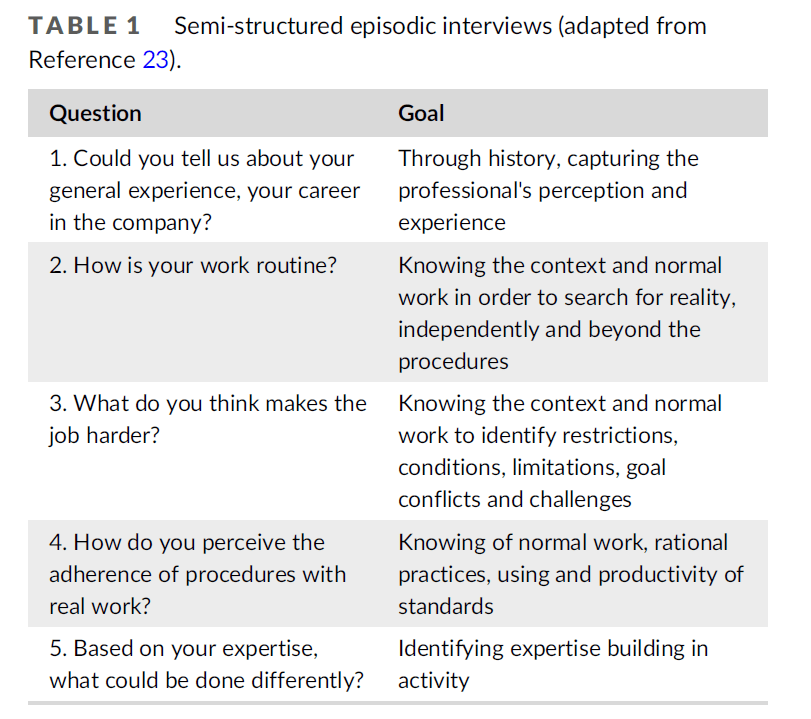

· “Learning from normal work requires the ability to ask questions that enable elaboration, free description, and reflection on the work context”

· They talk about techniques like safety critical task analysis and Learning Teams to facilitate learning

· “learning teams focus on the context surrounding the work and help identify system latencies or correlated defense weaknesses so they can be improved and thus prevent future problems”

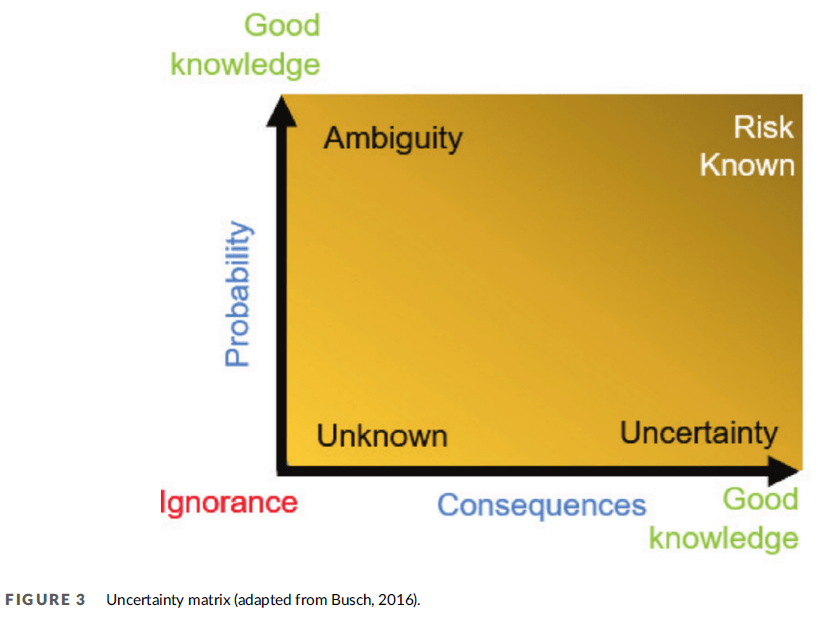

· Next they focus on risk – how it’s conceived etc. For one, the risk method “requires a careful approach to assess incomplete knowledge, “avoiding the temptation to treat every problem as a risk nail to be reduced by a probabilistic hammer”

· “experts should focus on neglected areas of uncertainty, and deeper challenges of ambiguity and ignorance”

· They present a risk & uncertainty representation that highlights risk where there’s good info about probabilities and consequences; a risk where “there is scarce knowledge about probability, but good knowledge about consequences, which is the “Uncertainty” that a given situation will occur”; there is “a “Risk” where there is good knowledge about probability, but little knowledge about consequences”, called ambiguity; and there is uncertainty where “both probabilities and possibilities are unknown”

· They say “Traditional risk analysis techniques, whose approach is based solely on calculating probabilities and consequences, focus on the (known ‘risk’ elements)”

· They discuss a few more things, including HRO

Marques LF, Fogaça LB, Henriqson E, Amario M. Learning from normal work in complex sociotechnical system—Case in midstream operation. Process Saf Prog. 2025;1‐9.

Shout me a coffee (one-off or monthly recurring)

Study link: https://doi.org/10.1002/prs.70022

Safe As LinkedIn group: https://www.linkedin.com/groups/14717868/