I’m putting together the next Research Compendium, covering indicator definitions, frameworks and examples.

Showing my own bias is a focus on Nancy Leveson’s work. This post has some extracts from her article ‘A Systems Thinking Approach to Leading Indicators in the Petrochemical Industry’.

This is based on what Leveson calls “assumption-based indicators”. That is, developing measures that monitor whether the system and control structure assumptions function as desired.

Some extracts:

· There are always warning signs before a major accident, but these signs may only be noticeable or interpretable as a leading indicator in hindsight. In fact, most major accidents have multiple precursors and cues that an accident is likely to happen”

· “Before an accident, such “weak signals” are often perceived only as noise. The problem then becomes how to distinguish the important signals from the noise”

· “To ask people to “be mindful of weak signals” is asking them to do something that is impossible”, and “There is always a lot of noise”, so the challenge is to distinguish important signals from noise

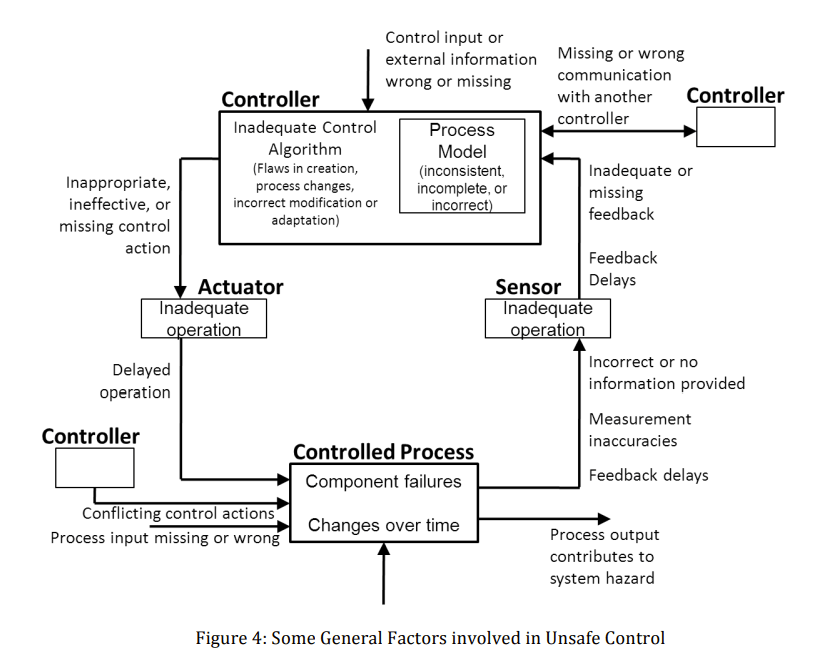

· Some of the typical safety control requirements which are inadequate are:

1) an action required for safety isn’t provided or not followed

2) An unsafe control action is provided, eg mud is removed before the well is sealed

3) A potentially safe control action is provided too early or too late,

4) A control action required for safety is stopped too early or applied too long

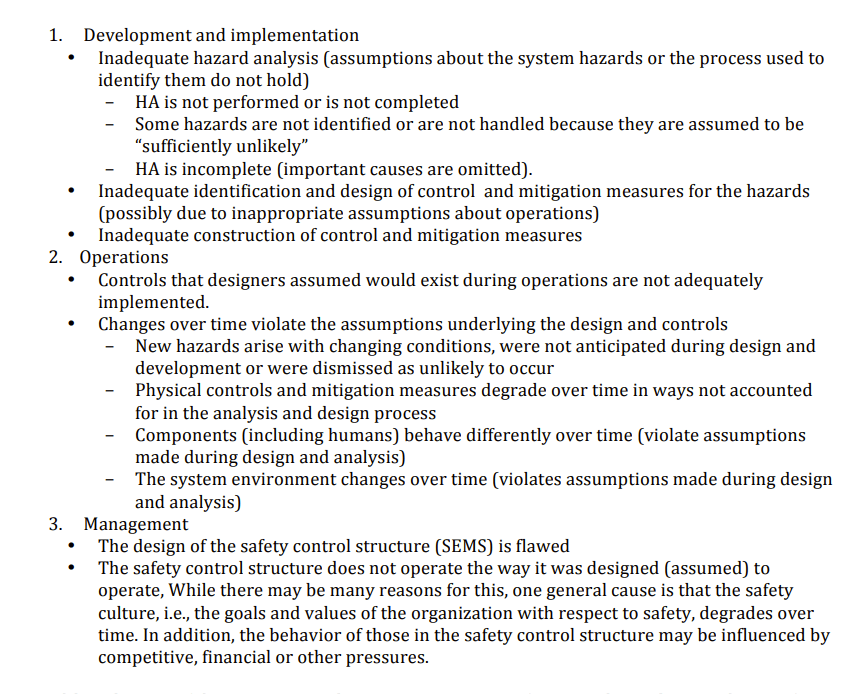

· A number of mechanisms are listed on how accidents can emerge in complex systems (image 3) – grouped under:

1) development and implementation (inadequate hazard analysis or control measures),

2) operations (controls that designers assumed would exist aren’t adequate in reality, emergence of new failure modes, degraded controls and more),

3) management (a flawed safety control structure, the control measure not operating the way it was assumed or designed to + more)

· Leading indicators are proposed as “warning sign that can be used to monitor safety-related assumptions, events or thresholds that, if detected, signifies that a safety-related assumption is broken or dangerously weak”

· Shaping actions, which are “intended to maintain assumptions”, and are “essentially actions taken during the design of the physical system … to prevent the violation of the assumptions”. They are feed-forward control mechanisms

· Hedging actions – “Actions that prepare for the possibility that an assumption will fail, including checking the assumptions during operations”. These stem from thinking about scenarios in which the safety control assumptions fail, and implementing means to detect or mitigate those scenarios”

I’ve put a link below to another paper from Leveson which shows worked examples of these indicators.

Ref: Leveson, N. G. (2013). A Systems Thinking Approach to Leading Indicators in the Petrochemical Industry.

Study link: https://dspace.mit.edu/bitstream/handle/1721.1/102957/esd-wp-2013-01.pdf?sequence=1&isAllowed=y

My site with more reviews: https://safety177496371.wordpress.com