This study explored the relationship between OHS enforcement from OSHA and a firm’s future violation behaviour (violation being penalties issued by the inspectorate).

Regression analysis based on a sample of 2,965 US manufacturers with 4,474 violation records issued by OSHA was analysed.

The following questions were explored:

1) Will firms take corrective action responsibly and seriously to reduce their chances of making similar mistakes (defined as violations of the same clause) in the future?

2) Do improved practices following receipt of a violation notice lead to a wider scope of improvement (i.e., extending to other clauses), or do firms irresponsibly just make quick clause-specific fixes that do not improve their overall safety performance?

3) Are firms with OHSAS 18001-certified systems and that are severely punished more likely to utilise past violation experience to improve their future safety performance?

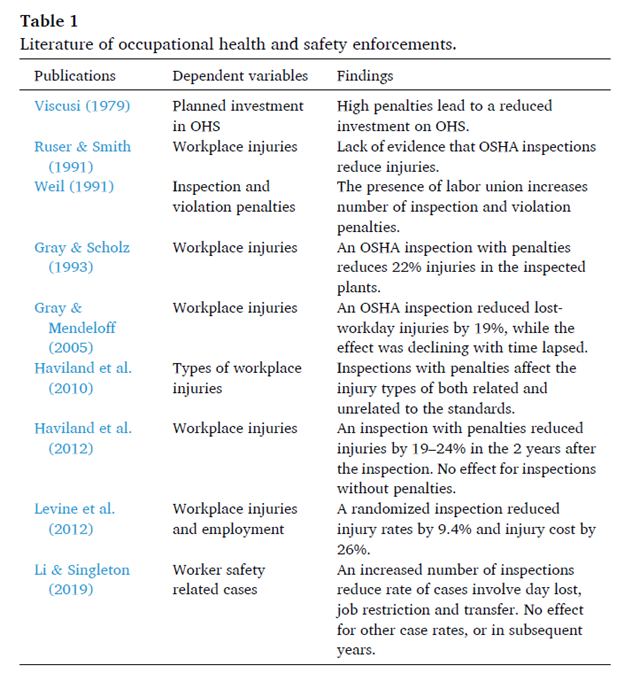

Providing background, they highlight some previous research on the efficacy of violations below:

Note. I’ve skipped most of the specific methods and statistical results as this runs over 6 pages.

Results

Key findings were:

· Past violation experience is negatively correlated with subsequent repeat violation incidents (that is, those experiencing violations in the past are less likely to experience them in the future); indicating “a certain level of improvement after a firm’s violation is detected and corrective action is taken” (p10)

· In contrast, past violation experience is positively correlated with subsequent non-repeat violation and overall violation incidents. That is, those with violations in the past are associated with higher overall violation histories and more likely to experience different types of violations. Subsequently, this “shows that firms do not necessarily reduce their number of safety violations as they accumulate more safety violation experiences” (p10)

· Interestingly, when firms are given severe past violation penalties/fines and also have OHSAS 18001 certified systems, they display “greater tendencies to extensively and proactively learn from their past violation experiences, leading to a reduction in subsequent overall violations” (p10)

They argue that these findings “are intuitive in that they show that these experiences help reduce future similar mistakes, while it is counterintuitive to find that violation experiences increase future non-repeat and overall violations” (p10).

They speculate on why this may be the case with some plausible mechanisms:

1) Prior research has found a similar trend with product recalls. Whereas legal enforcement may increase a firm’s operational systems, “the lessons learned from previous mandated product recall experiences can be shallow and symbolic, leading to no fundamental improvement in firms’ product safety routines and practices” (p10)

Moreover, in line with other research, it’s possible responses to violations from government authorities “may simply be adaptive and reactive within a limited scope” (p10)

2) A phenomenon of “organizational myopia”. That is, “adaptive corrective actions could cause firms to overlook the big picture and other potential failures” (p10). They note this especially the case when such adaptive improvements are mandated by external parties.

3) OSHA penalties are too low. Economically, if the expected penalties are smaller than the investment required to mitigate potential issues, then the deterrent effect of violations would be less sufficient to motivate proactive improvement.

These findings show that an increase in violation penalty may enhance the effectiveness of enforcement; in line with another recent study finding that penalty magnitude could reduce a firm’s environmental violations.

Finally, they discuss how these findings extend the research field around the use and benefits of OHS certification; in this case OHSAS 18001. Some prior work has shown that OHSAS 18001 certification had a direct positive impact on a firm’s safety performance, including safety climate and the number of safety violations and accidents. This study extends those findings by highlighting how certification may also improve performance via regulatory enforcement.

Authors: Fan, D., Yeung, A. C., Yiu, D. W., & Lo, C. K. (2022). International Journal of Production Economics, 248, 108481.

Study link: https://doi.org/10.1016/j.ijpe.2022.108481

Link to the LinkedIn post: https://www.linkedin.com/pulse/safety-regulation-enforcement-production-role-systems-ben-hutchinson

One thought on “Safety regulation enforcement and production safety: The role of penalties and voluntary safety management systems”