This study, among a few other things, compared 633 incidents against >9 inspection reports with similar contexts to understand the overlap. Data was from a Canadian construction project over 3 years.

E.g. They used multi-methods, including natural language processing, text mining, bow ties and more to evaluate if field inspections are looking at the same failure points that are identified in investigations (** that oversimplifies it, but hopefully represents what they did).

** NB: I had a fair bit of trouble interpreting all of the methods and findings in this study, so I’ve likely made more mistakes than usual.

For context:

· Some research suggests that an absence of “periodic safety inspections can increase the rate of accidents by 40 %”

· They say that for organisations that collect and analyse inspection records, the inspection records “are rarely analyzed more than once to serve as performance indicators”

· Further, “Tang et al. (2020) reported that inspection frequency is inadequate for identifying and eliminating hazards promptly”

· And “Beyond frequency and timeliness, most audits/inspections fail to identify deficiencies that lead to a serious incident or fatality (Hutchinson et al., 2024)”

· Hence, we need to know whether the inspections are effective rather than just counting their frequency

· They cover research on the limitations of TRIR etc, e.g. “injury rates have severe statistical limitations and are invalid for nearly all practical purposes because injuries are numerically rare (e.g., 1 per 200,000) and are approximately 98% random unless it is derived from several hundred million work hours (Hallowell et al., 2021; Erkal et al., 2023”

Results

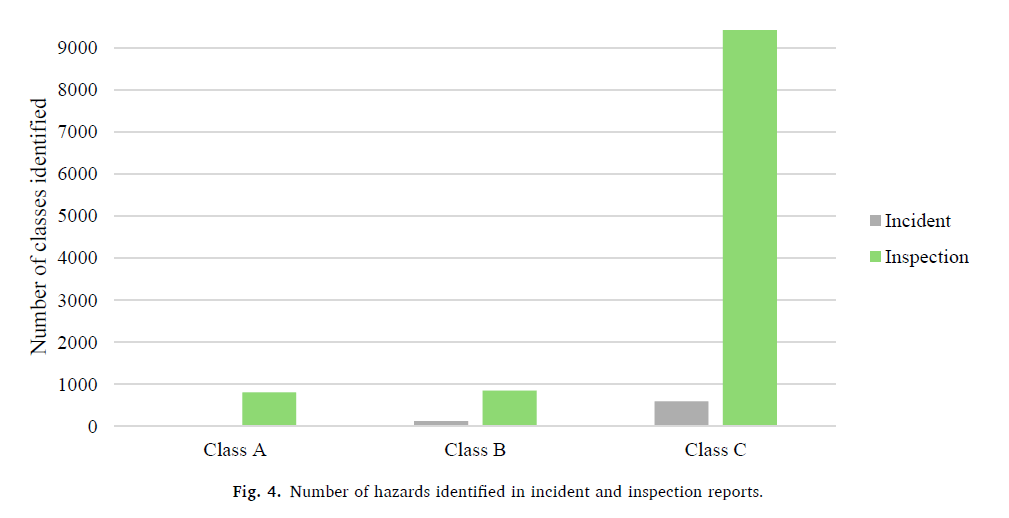

Key findings were that:

· “The results demonstrate that the indicators that cause incidents with the most severe consequences and are inadequately captured during inspections are: working at heights (81%), equipment handling/storage (17%), and ergonomics (0.4%)”

· That is, whereas incidents most frequently relate to factors of WAH, equipment handling and ergonomics, but proactive inspections evaluate these factors in 81%, 17% and 0.4% of the time

· The authors refer to these gaps as blindspots

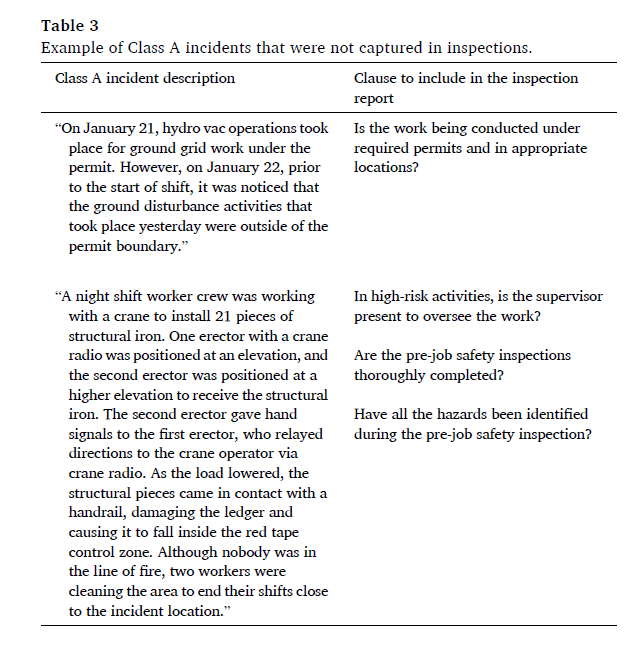

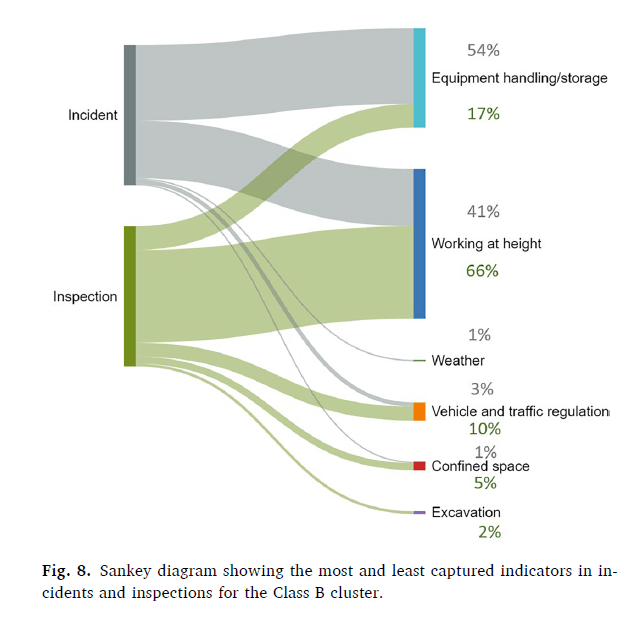

They divided incident severity into A, B, C (A being the most severe). For B class, they found that 17% of inspections related to equipment handling storage whereas 54% of accidents related to the same factor. However for class B WAH incidents, the relationship was reversed with 41% of incidents involving WAH whereas 66% of inspections involved WAH.

For class C, 73% of incidents involved ergonomics, yet just 0.4% of inspections focused on ergonomics. In contrast, housekeeping was the most discussed factor in inspections.

They note that “specific topics are generally given more attention during inspections (i.e., housekeeping) because these are easier to see”. Hence, organisations need to direct more planning and resources towards the less observable and more severe factors.

Their findings highlighted what sorts of issues/precursor issues were being captured by the current investigation & inspection regimes, and “importantly, which are not”.

Hence, these sorts of comparisons can help organisations to target the most pertinent issues, and ensure that their inspection and verification activities are accurately coupled to the principal hazards.

Ref: Elizabeth, R. M. C., Sattari, F., Lefsrud, L., & Gue, B. (2025). Visualizing what’s missing: Using deep learning and Bow-Tie diagrams to identify and visualize missing leading indicators in industrial construction. Journal of Safety Research, 93, 1-11.

Study link: https://doi.org/10.1016/j.jsr.2025.02.007

My site with more reviews: https://safety177496371.wordpress.com

Shout me a coffee: https://buymeacoffee.com/benhutchinson

LinkedIn post: https://www.linkedin.com/pulse/visualizing-whats-missing-using-deep-learning-bow-tie-ben-hutchinson-4ciyc